When metals are exposed to the elements or certain chemicals, degradation in the form of oxidation can occur. The second law of thermodynamics states that everything tends toward disorder. After designing and manufacturing a product, the last thing you want is for metal components to break down through oxidation, corrosion, or rust.

While oxidation and deterioration are age-old problems, there are ways to mitigate them. One of the best solutions is applying protective coatings to parts to shield them from natural elements or harsh chemicals that cause degradation. Conversion coatings are an example of such protective layers—they remove surface impurities and strengthen the metal part’s oxide layer.

What Are Chemical Conversion Coatings?

Chemical conversion coatings are thin layers formed on metal surfaces, composed of oxides, phosphates, or chromates. They are applied by immersing metal parts in a chemical bath, triggering a reaction between specific reagents and the part’s surface. This reaction is a redox process where a small amount of surface metal (particularly metal oxides and impurities) is removed and replaced with a more uniform, resilient oxide layer than the naturally occurring one. The amount of metal/metal oxide removed typically ranges from 0.00001 to 0.0001 inches—for context, the natural oxide layer on aluminum is much thinner.

Comparison of Conversion Coatings

| Coating Type | Coating Structure | Properties | Applications |

|---|---|---|---|

| Anodizing | Dense barrier layer with a porous outer layer. | Corrosion and scratch resistance; non-conductive. | Aesthetics, lubrication, corrosion protection. |

| Chromate Conversion (Chemical Film) | Non-porous, moisture-resistant film, primarily chromium oxide. | Corrosion resistance; enhances paint adhesion; inhibits further corrosion if damaged. | Marine applications; decorative use; paint adhesion on non-porous layers. |

| Black Oxide | Formed from stable iron oxide (magnetite). | Inhibits rust (iron oxide) formation; absorbent; improves wear resistance. | Enhanced aesthetics; rust prevention. |

| Phosphate | Crystalline structure of phosphate compounds (iron, zinc, or manganese phosphate) formed on the surface. | Highly absorbent and chemically inert surface. | Good paint adhesion with iron; prevents severe wear or seizing. |

Examples include chromate conversion coatings (CCC), phosphate conversion coatings (PCC), and black oxide coatings. During the conversion process, part of the metal surface is transformed into a protective layer, such as chromate, phosphate, or black oxide films. A chromate conversion coating on an aluminum substrate is a type of chemical film.

Additionally, nanopores within the oxide crystal layer can often be filled with dyes or sealants to enhance properties like color, lubricity, and hardness. Crucially, the metal oxide layer is chemically bonded to the metal it protects, making conversion coatings highly durable and resistant to penetration.

Benefits of Chemical Conversion Coatings

Chemical conversion coatings can positively impact part appearance, galvanic corrosion affinity, conductivity, hardness, and oxidation resistance. Key advantages include:

- Reduced corrosion rates

- Improved wear resistance and durability

- Enhanced adhesion of organic coatings (e.g., paint or powder coating)

- Increased ability to stretch or form metal without damage

- Customizable coloring or staining for decorative purposes

- Applicable via simple methods (spraying, dipping, brushing)

Ultimately, applying a conversion coating helps extend part lifespan and adds desired properties like color, hardness, lubricity, or enhanced corrosion resistance. Keep these common conversion coatings in mind when designing your next product!

Conversion Coatings for Aluminum

Anodizing

Anodizing is a common form of electrolytic passivation for aluminum (and steel, though we focus on aluminum here). First, parts are typically cleaned and/or descaled to remove deposits or heavy contaminants. Next, a sulfuric acid or other acid bath strips (etches) away any naturally occurring oxide layer. The parts are then connected to a power source to give them a positive charge and immersed in an anodizing bath—an acid solution where an electric current passes through the part (acting as the anode in the circuit). In the bath, the part attracts negatively charged oxygen ions directly to its surface.

The nanopores in the metal oxide crystals formed during this process can be filled with dyes and sealed in another chemical bath to achieve various colors. Thanks to its vibrant color range, anodizing is often used for consumer goods.

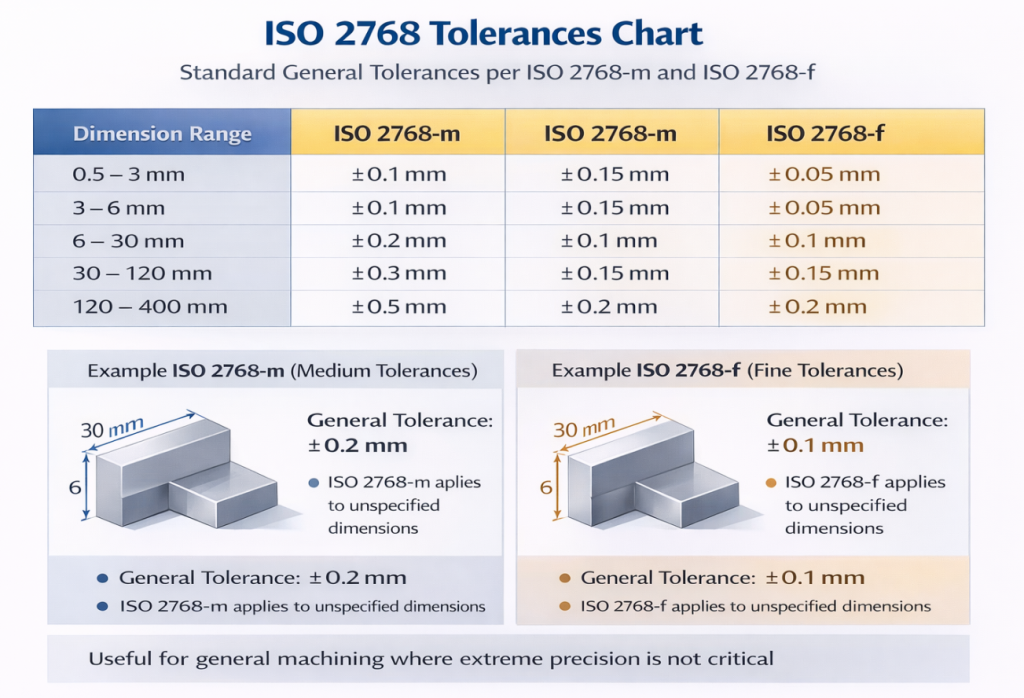

Anodizing adds a small amount of material to the part surface, causing it to “grow”—standard anodized coatings reach thicknesses of a few thousandths of an inch. For parts requiring tight tolerances, account for this in your design, using masking or hole plugs in critical areas before anodizing.

Note that different anodizing processes (Type I/1B, Type II, Type III/III with PTFE) result in varying layer thicknesses. These variations make the coating suitable for industries ranging from aerospace (e.g., International Space Station trusses) to art and sports equipment.

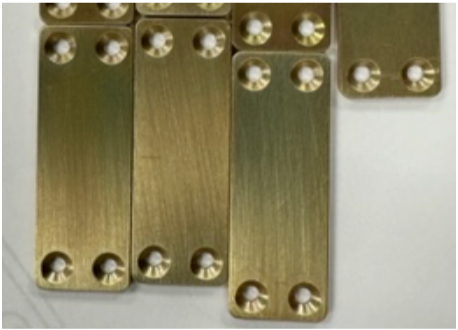

Chemical Film or Alodine™

Chromate conversion coatings, known as chemical films or chromates, are similar to anodizing in that they create a modified, corrosion-resistant oxide layer on metal parts but do not use electricity to form the layer. Alodine™ is a brand name for chemical conversion coatings produced by Henkel (other brands include Iridite®, Bonderite®, and Chromicoat®). Think of chromates as a chemical alternative to anodizing. Chemical films or Alodine™ are effective corrosion-resistant surface treatments for aluminum, used in painting, powder coating, adhesive bonding, radiators, and automotive wheels.

Unlike anodizing, chemical film/Alodine™ is a purely chemical process using reactive chromium atoms. To apply it, parts are first cleaned, degreased, and rinsed, then immersed in a chromium bath, removed, rinsed, and dried. It is often applied to screws, bolts, brackets, and other fasteners as it causes minimal dimensional change. Chemical film/Alodine™ is cheaper than anodizing but more prone to wear and scratching.

The most common types of chromate conversion coatings (chemical films) are:

- MIL-DTL-5541 Type 1: Contains hexavalent chromium (“hex chrome”).

- MIL-DTL-5541 Type 2: Replaces hexavalent chromium with trivalent chromium, titanium, or zirconium.

Historically, hexavalent chromium compounds were the primary catalyst in chemical films/Alodine™. However, due to their carcinogenicity, hexavalent chromium is strictly regulated, and trivalent chromium (including Type 2) is now widely accepted as the standard (“hex-free” chromates).

Chromate conversion coatings also have different classes:

- MIL-DTL-5541 Class 1A: Thicker, darker, and offers higher corrosion protection.

- MIL-DTL-5541 Class 3: Thinner, reduces galvanic corrosion, and maintains conductivity.

These types and classes provide multiple options; the best choice depends on your project’s needs.

| Quality | Anodizing | Chemical Film (Alodine™) |

|---|---|---|

| Thickness | 1.8–25 microns | 0.25–1.0 microns |

| Conductivity | No | Yes |

| Appearance | Multiple colors | Transparent/gold |

| Types | Type I/1B, II, III/III with PTFE | Type 1, Type 2 (Class 1A, 3) |

| Materials | Aluminum and others | Aluminum and others |

| Price | $$$ | $$ |

| Durability | **** | ** |

Table 2: Comparison of Anodizing and Chemical Film (Alodine™)

Can Anodizing and Chemical Film (Alodine™) Be Used Together?

While applying both coatings won’t harm parts, it offers little benefit. Both create improved surface layers for corrosion resistance—once one coating is applied, the other adds no extra paint adhesion or corrosion protection. An exception may be repairing damaged areas of a previous coating.

Some CNC-machined aluminum parts require painting on specific surfaces and plating/coating on others. For such parts, you can anodize certain areas and apply chemical film/Alodine™ to others.

Conversion Coatings for Steel or Stainless Steel

Black Oxide

Black oxide, historically called browning or bluing, is a conversion coating most commonly used for steel and stainless steel. Similar to chemical film/Alodine™, it is a purely chemical process that produces a conductive iron oxide layer (magnetite) to protect the base metal from corrosion.

Black oxide surfaces significantly reduce metal reflectivity and cause minimal dimensional change. When sealed with oil or wax, they gain lubricity, making them ideal for parts like gears and locks to prevent wear. Black oxide can also be applied to copper and steel.

Black Oxide vs. Passivation

Both processes enhance corrosion resistance and aesthetics for stainless steel parts. Black oxide is a chemical conversion process, while passivation is a chemical treatment that removes free iron from the stainless steel surface to promote a protective oxide layer. Stainless steel has a natural oxide layer, but free iron on the surface reacts with oxygen in air to form rust (iron oxide). Passivation offers better rust protection, while black oxide provides moderate rust resistance and improves surface appearance.

| Quality | Passivation | Black Oxide |

|---|---|---|

| Thickness | 5–15 microns | < 0.75 microns |

| Conductivity | No | Yes |

| Appearance | Smooth, glossy | Smooth, matte black |

| Types | Zinc or manganese seal | Various procedures |

| Materials | Steel, stainless steel, etc. | Steel, stainless steel, etc. |

| Price | $$$ | $ |

| Durability | *** | ** |

Table 3: Comparison of Passivation and Black Oxide

How Do Conversion Coatings Differ from Electroplating?

At first glance, electroplating and conversion coatings may seem similar. Electroplating is an electrochemical process where metal is deposited on a part’s surface. This thin protective layer can alter appearance, physical properties, wear resistance, biocompatibility, or conductivity. Electroless plating is a similar process where metal is deposited without electricity (e.g., electroless nickel).

The key difference: electroplating forms a layer of a different metal on the part surface via electrochemistry, while chemical conversion coatings form a non-metallic film through chemical reactions. Electroplated layers are much thicker than chemical conversion coatings.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.