This chair, designed through the 3DEXPERIENCE platform, is printed and formed as a single-piece folding structure.

French designer Patrick Jouin has long explored the geometric freedom of additive manufacturing, creating a series of groundbreaking furniture pieces, including an integrated 3D-printed bench with internal rib structures, which was exhibited at the Palais de Tokyo in Paris. This month, the designer unveiled his latest 3D-printed work, the Ta.Tamu chair—also featuring an integrally formed and foldable design.

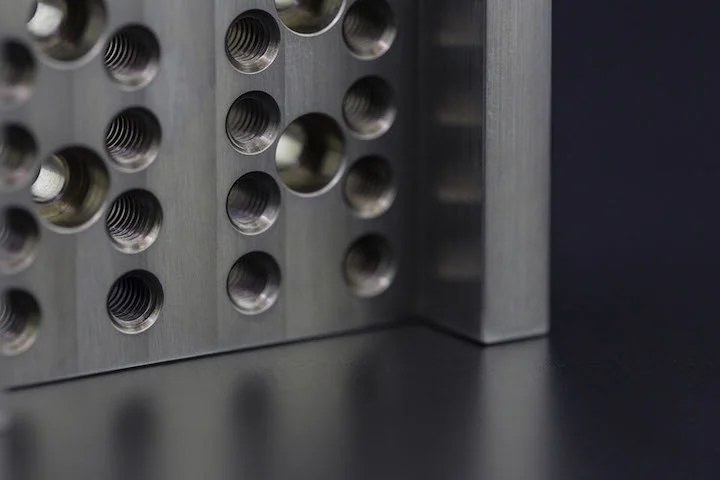

Years in the making (an iterative upgrade based on the earlier Tamu chair), this chair adopts a bionic organic structure, drawing on the mechanical principles of bones and joints to create a single-piece structure that can fold independently and bear weight. The final product is 3D-printed in a planar form using polymer powder sintering technology, then unfolded into shape via 33 movable joints—no connectors or assembly processes required at all.

Dassault Systèmes’ generative design platform, 3DEXPERIENCE, serves as the core technical support for the project. The designer leveraged AI-driven virtual twin technology to create the unique structure. “This process is built on a continuous dialogue between the designer’s intuition and the intelligence of digital tools,” Jouin explains. “Each iteration brings structural optimization, printing tests, and physical validation… Inspired by the logic of skeletal structures, the final form is both lightweight and strong—distributing material only where necessary, just like human tissue. It is a computationally generated form, but by no means an automated product; it is the result of a patient dialogue between creativity and algorithms.”

The chair can support a weight of 100 kilograms (220 pounds) while weighing only 3.9 kilograms (8.6 pounds)—a 75% weight reduction compared to a solid-filled design. Lightweighting is a key design principle for Jouin, with his philosophy encompassing both sustainability and material efficiency. In other words, the designer strives to achieve optimal functionality with the least amount of material. “We live in an era of overproduction,” Jouin notes. “With new collaborative technologies, we can now improve efficiency and reduce waste right from the design stage.”

The Ta.Tamu chair is essentially a proof of concept for “human-machine collaborative creation”: the skills of human designers and the capabilities of generative design empower each other, jointly exploring new paradigms to enhance material economy. Notably, the software is not only used for topology optimization modeling but also simulates structural behavior—verifying the unfolding mechanism and load-bearing capacity before printing, further strengthening the project’s material efficiency.

“To improve our living environment, we must transform the way we produce, design, and use materials,” adds Anne Asensio, Vice President of Design Experience at Dassault Systèmes. “Ta.Tamu is a call to action for industries—to replace unlimited production with a generative economy. This creation employs key technologies for sustainable innovation in the industrial sector.”

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.