Aluminum is the second most used metal after steel, with a wide range of applications from construction to aerospace. Aluminum stamping is a manufacturing process used to produce aluminum parts in desired shapes. There are many aluminum alloys, and 6063, 2024, and 5083 are commonly used in aluminum stamping. This article contains information about aluminum stamping, including how it is done, which alloys are used, and the costs of these processes.

What is Aluminum Stamping?

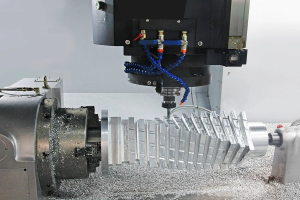

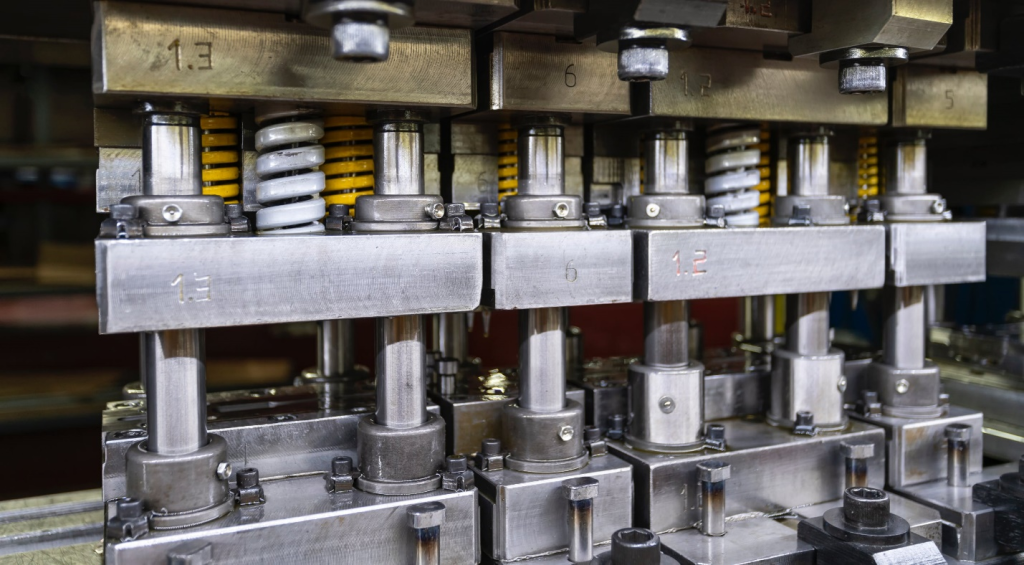

Aluminum stamping is similar to the forging process and is used in manufacturing. In this process, an aluminum sheet is placed between two dies. These top and bottom dies contain the desired shape. One of the dies is fixed, and the other moves vertically. When you place the sheet and press the dies, the sheet is transformed into the desired shape.

Detailed Explanation of Precision Aluminum Stamping Process

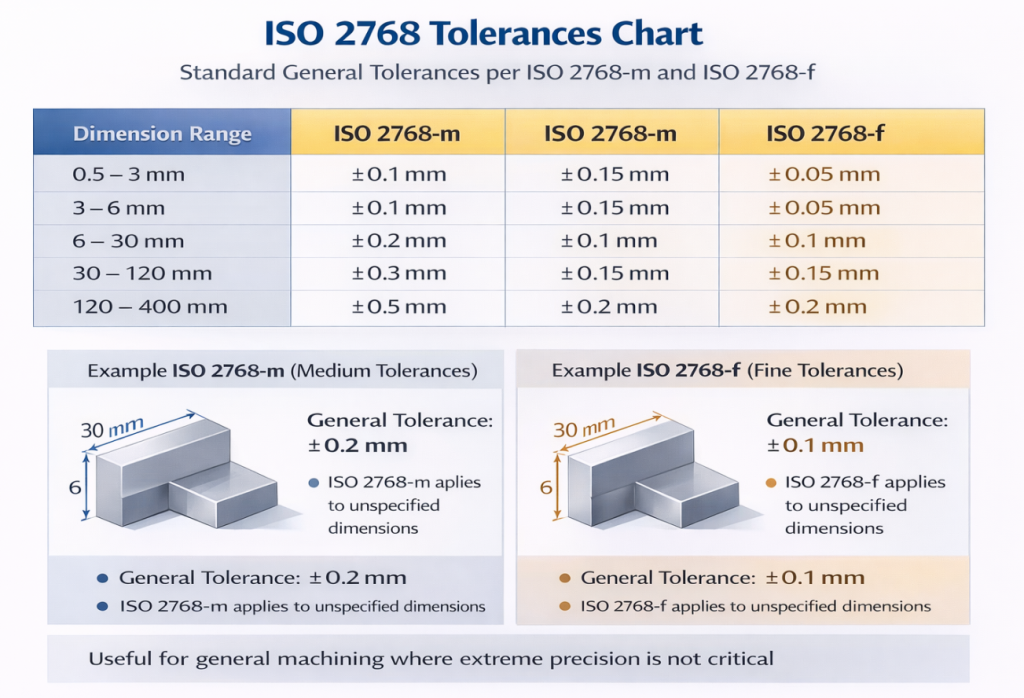

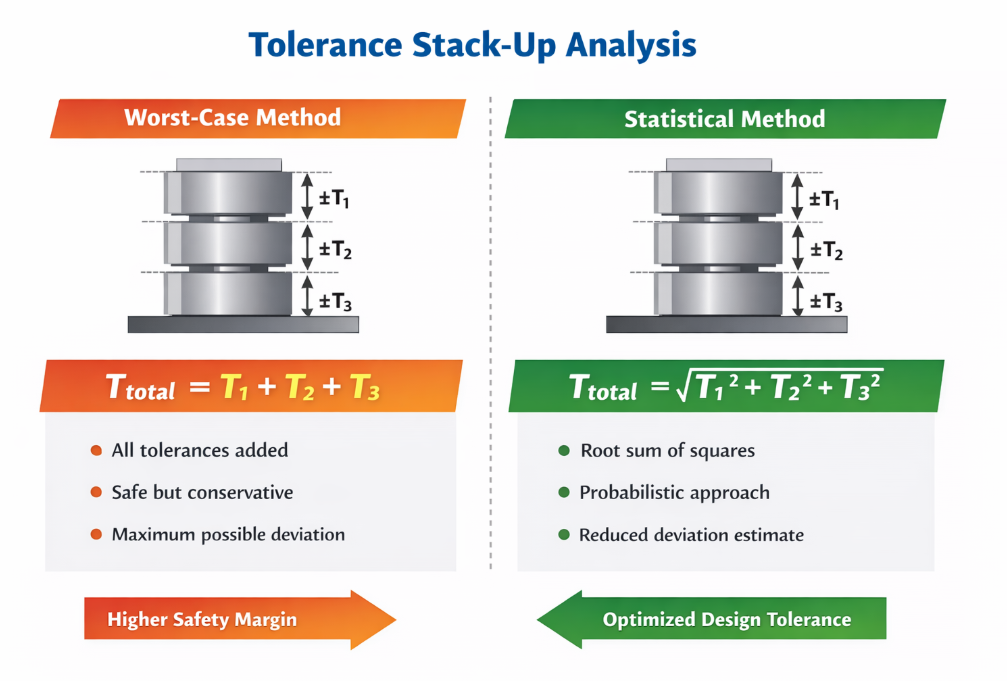

Aluminum stamping is a step in the manufacturing process. It produces parts with high precision. After the stamping process, the metal sheet takes on a shape that is difficult to machine because excess material is removed during the process. To achieve tight tolerances and additional precision, you need to perform additional operations such as grinding and polishing.

Why Choose Aluminum for Stamping?

Aluminum has better machinability and does not burn during heating. It has a lower melting point, so aluminum can undergo the stamping process at lower temperatures and in a shorter time. After cooling, aluminum becomes stronger.

Advantages of Stamping Aluminum

There are many advantages to using aluminum for the stamping process. For example:

- Aluminum is a lightweight metal with high strength, which can be used to manufacture many components of aircraft. Aluminum is easy to process and does not require higher loads or temperatures to deform.

- Aluminum has strong corrosion resistance, so it is very suitable for critical applications such as aerospace and automotive.

- Aluminum is a common metal, which is why it is not that expensive. This is why we usually use aluminum for stamping processes. The ease of processing and manufacturing of aluminum makes it a cost-effective material. This is a great advantage that can save money and time.

- Aluminum has very good mechanical properties; for example, high ductility and medium strength are major advantages. Its high ductility allows aluminum sheets to be easily transformed into desired shapes. This property enables us to manufacture complex structures from automotive to aircraft components.

Common Challenges in Aluminum Stamping

This section will introduce you to some challenges that may be encountered during the aluminum stamping process:

Galling and Wear Issues

This is the most common challenge in the stamping process. In this challenge, aluminum material adheres to the die surface, making the aluminum surface rough. This surface will shorten the service life of tools or components and cause financial or material losses. To alleviate this problem, you can use lubrication or preheat the die.

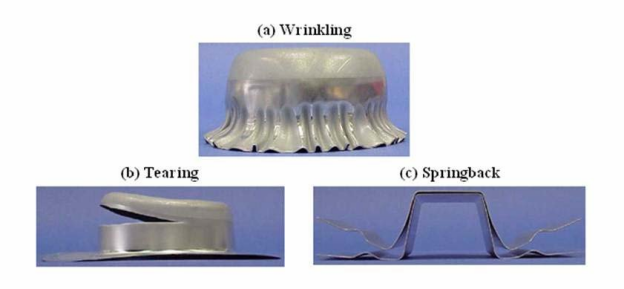

Springback of Aluminum Parts

Because aluminum metal is lightweight, it is a common phenomenon for stamped aluminum parts to return to their original position. Springback can cause some serious injuries, so it should be avoided by managing precise tool adjustments.

Wrinkling and Tearing

There are two main reasons for these problems:

- High compressive stress

- Very high blank holder force (the force that presses the material into the die)

To avoid this problem, you should optimize the die design and stamping speed.

Tool Wear and Maintenance

Tool wear occurs during the stamping process, and the main tool is the die. When the die is cold, materials at 400-500°C enter the die, causing the die to crack. This can be solved by preheating the die and performing daily maintenance.

How to Calculate Aluminum Stamping Costs

If you are interested in preparing a batch of aluminum parts through the stamping process, you can calculate it yourself according to the following standards.

Material Costs

The type of material is an important factor affecting the total cost. There are more than 500 types of aluminum alloys in total; some are easy to process, and some are difficult. Another factor is the thickness of the sheet. Very thin and thick aluminum sheets are difficult to transform into the desired shape.

Die Costs

Remember that tools may be damaged during processing or production. Therefore, these tools and dies require proper maintenance due to wear. This is why you should calculate the tooling costs before choosing any manufacturing method.

Production Costs

Production costs involve electricity costs, production volume, type of supplier (domestic or international), etc.

Some workpieces require higher press tonnage (the force required to cut aluminum metal during stamping), which will affect the total cost. Higher tonnage means higher energy consumption, so the final cost will also be higher.

Cycle time refers to the time required to complete one production cycle. The shorter the cycle time, the higher the productivity, and thus the lower the production cost.

The higher the production volume, the lower the total cost. If the press tonnage is inconsistent throughout the process, tool maintenance costs will increase.

Labor Costs

You can manufacture your products through automatic or manual aluminum stamping processes.

- In the manual stamping process, you will need more labor, which means higher costs because the number of stampings per day increases. The possibility of human error is higher, production speed is slow, and efficiency is low. In this process, the skill level of the labor is not that important.

- In the automatic stamping process, you need fewer workers, which means fewer stampings per day, so the overall cost will be lower. But the main difficulty is the installation cost of these machines. Operators must be very skilled to operate the automatic stamping process.

Surface Treatment Costs

The stamping process cannot produce parts with a very smooth surface. After the stamping process, some scraps will remain on the surface and must be removed. To obtain better surface roughness, you need further processes such as polishing, anodizing, or certain types of coatings. These processes will increase the total cost.

Overhead and Maintenance

Overhead costs refer to maintenance costs used to keep equipment in good working condition. Maintenance costs include daily maintenance tools, some repair costs, etc. Other costs include electricity usage and depreciation (when equipment wears out).

Transportation and Logistics

Transportation and logistics costs refer to the funds spent on transporting materials or machines. These costs depend on the amount of materials, fuel prices, the weight of aluminum parts, and the distance between two locations.

Methods to Reduce Costs

We have previously studied the factors that lead to cost increases. Now, the following methods will help you control the overall cost:

- Design optimization

- Increase batch size

- Use cost-effective materials

Applications of Aluminum Stamping in Various Industries

Let’s understand the uses of aluminum stamping:

Aerospace Industry

- Wing panels

- Fuselage components

Aluminum is a lightweight, low-cost, and corrosion-resistant metal, which is why it is widely used in the aerospace industry.

Automotive Industry

Aluminum stamping is used to manufacture the following parts:

- Various components

- Body panels

- Engine parts

Electronics and Consumer Goods

- Casings

- Connectors

- Brackets for electronic devices

Medical Device Manufacturing

- Surgical equipment

- Diagnostic equipment

- Components of various medical devices

Construction and Architecture

- Picture frames

- Panels

- Structural supports

Common Aluminum Alloys in Stamped Sheet Metal Parts

Each series of aluminum alloys has specific properties:

1100 Aluminum Alloy

The 1100 aluminum alloy series is suitable for stamping because of:

- Excellent corrosion resistance

- Workability

3003 Aluminum Alloy

This series is often used in stamping applications due to its strength and corrosion resistance.

5052 Aluminum Alloy

It can be used in critical applications such as automotive and aerospace for the following reasons:

- Strength-to-weight ratio

- High durability

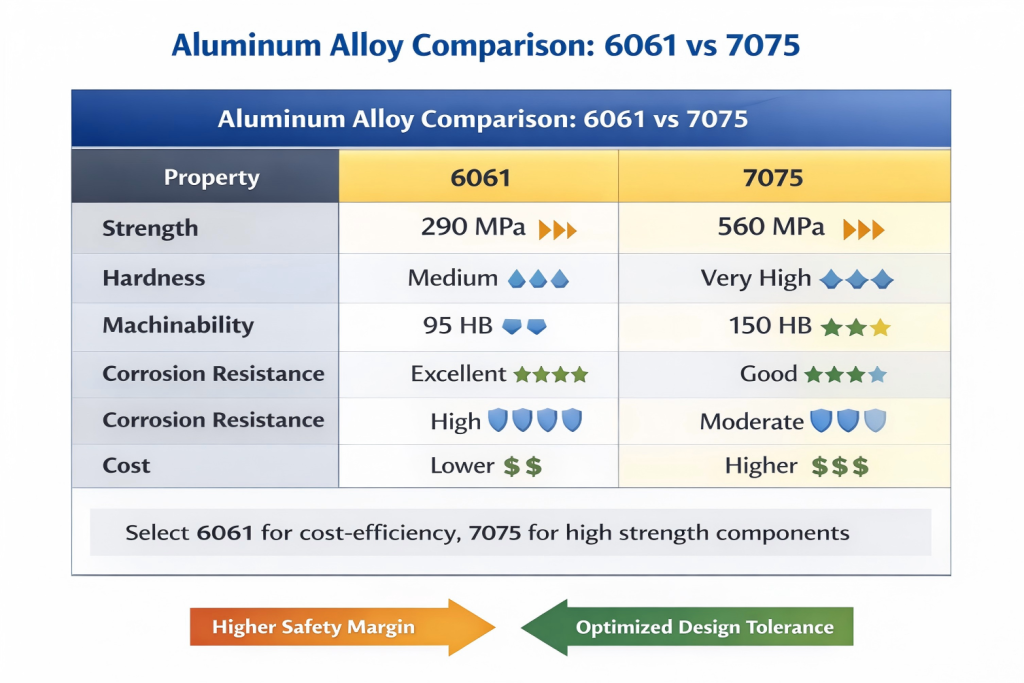

6061 Aluminum Alloy

This alloy becomes stronger after heat treatment and is suitable for high-performance applications.

6063 Aluminum Alloy

This alloy can be used for stamping due to the following characteristics:

- Lightweight design, easy to move

- Formability

- Corrosion resistance

- Excellent weldability

2024 Aluminum Alloy

The following characteristics are the reasons why we use this alloy in the stamping process:

- Good formability

- Higher strength and durability

- Good weldability

- Higher fatigue resistance

7075 Aluminum Alloy

This grade is used in aerospace and automotive fields because of:

- Good machinability

- Fatigue resistance

- High strength-to-weight ratio

5083 Aluminum Alloy

5083 aluminum alloy parts are widely used in marine, aerospace, and automotive industries for the following reasons:

- Good weldability and formability

- Excellent fatigue and corrosion resistance

Aluminum Alloy Ladder for Stamped Parts

| Alloy | Composition | Key Properties | Applications |

|---|---|---|---|

| 2024 | Aluminum-Copper | Higher fatigue resistance and strength | Aerospace structural parts |

| 5052 | Aluminum-Magnesium | Excellent formability | Marine, fuel tanks |

| 5083 | Aluminum-Magnesium | High strength, corrosion resistance | Marine corps, defense |

| 6061 | Aluminum-Magnesium-Silicon | Excellent machinability | Aerospace and automotive |

| 7075 | Aluminum-Zinc-Magnesium-Copper | High strength-to-weight ratio | High-performance parts |

| 3003 | Aluminum-Manganese | Higher fatigue strength | Roofing, siding |

| 1100 | Pure aluminum | High ductility | Chemical equipment |

Key Considerations for Choosing Alloys

Before selecting an alloy profile, the following factors should be considered:

- Application field

- Mechanical properties

- Machining performance (weldability, formability, etc.)

Impact of Alloy Properties on Stamping Quality

Choosing the wrong alloy may affect the following:

- Surface finish

- Durability of components

- Formability

- Metal stamping equipment

- Tool wear

Types of Aluminum Stamping Operations

There are various types of stamping operations:

Blanking Aluminum

In the first step of aluminum stamping, the flat sheet is transformed into the desired shape.

Punching and Cutting Aluminum

- Punching: Making holes in the stamped aluminum sheet

- Cutting aluminum: Making internal cuts

Embossing and Coining Techniques

- Coining: High-pressure stamping to leave marks on the stamped sheet

- Embossing: Used for re-evaluating designs on aluminum sheets

Deep Drawing Aluminum

In the deep drawing type of aluminum stamping, the aluminum sheet is pulled into the die cavity to produce complex shapes.

Flanging Aluminum Parts

This process is responsible for bending the edges of aluminum sheets to manufacture parts suitable for automotive components.

Specialized Aluminum Stamping Technologies

You should use the following specialized aluminum stamping technologies:

Progressive Die Stamping

- Used for mass production of aluminum stampings

- Ensures consistent quality and saves costs

Transfer Die Stamping

It is a metal stamping aluminum process used to manufacture larger and more complex stamped aluminum sheet components.

Four-Slide Stamping

This is an aluminum stamping process characterized by:

- Best suited for stamping processes, suitable for producing high-precision, small complex parts

- Used in electronics and medical equipment

Fine Blanking of Aluminum Parts

This process is used to produce parts with neat edges and tight tolerances.

Aluminum Stamping and Surface Treatment

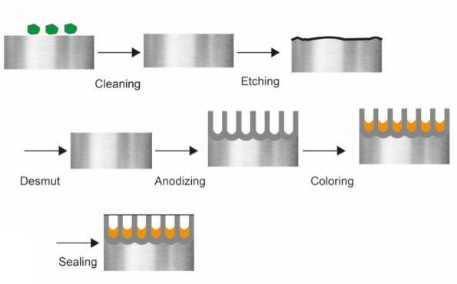

The aluminum stamping process alone is not sufficient to produce a good surface finish; therefore, you need to complete the following processes to obtain the desired surface finish:

Anodizing Stamped Aluminum Parts

Anodizing makes stamped aluminum components resistant to corrosion even in harsh conditions. Anodizing is a coating process that deposits an oxide layer.

Lubrication Technologies for Aluminum Stamping

- Oil-based lubrication: Spraying/dipping; suitable for heavy-duty stamping

- Water-based lubrication: Spraying or wiping; environmentally friendly

- Dry film lubrication: Coating/brush application; very suitable for high-temperature applications

- Synthetic lubrication: Can be sprayed or rolled

Preventing Oxide Buildup During Stamping

You can use one of the following methods:

- Anodized aluminum

- Ultrasonic cleaning with dilute hydrochloric acid

- Using wire drawing and beading

Debaolong Seiko: Aluminum Stamping Parts Supplier

Debaolong Seiko adopts the most advanced stamping technology to ensure the precision and tolerance of aluminum components. We know that aluminum is used in critical industries, so we will use advanced machines to be responsible for the precision machining of components. You can also come to us for custom tool and die design. Products will be delivered at a faster speed and at the most favorable price.

Frequently Asked Questions (FAQ) About Aluminum Stamping

Why is Aluminum Increasingly Used in Automotive Production?

Because it has a high strength-to-weight ratio, corrosion resistance, light weight, and fatigue strength.

How Thick of Aluminum Can You Stamp?

Aluminum sheets with a thickness of 0.2mm to 0.6mm can be stamped.

Aluminum Stamping vs. Steel Stamping

Compared with steel, stamping aluminum is easier because:

- Lower temperatures are required for deformation

- It is softer than steel, so lower pressure loads are required

- Easier to machine and weld

What are the Best Lubricants for Aluminum Stamping?

- Emulsions

- Hot melt lubricants

- FDX 240 A

Conclusion: Why Aluminum Stamping is a Valuable Manufacturing Process

After reading this article, we can conclude why aluminum stamping is a valuable manufacturing process. There are many reasons, such as it can be performed using automatic machines, is suitable for stamping multiple aluminum alloy series, and can be used for complex components from large to small. To obtain the final surface finish, you need to apply further operations such as polishing.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.