In design and machining, holes are central to the construction and functionality of various parts. They serve specific purposes, from housing components to connecting sensors or facilitating fluid flow. Among different types of holes, blind holes are a crucial category. This article explains blind holes, exploring their definition, significance in design and machining, and applications across industries.

Definition and Purpose of Holes in Engineering

In design terminology, a hole is an intentionally created void in a material to fulfill a specific objective. Holes have diverse functions, such as reducing weight, enabling part assembly, or allowing the flow of liquids and gases. Understanding the purpose of a hole is essential for designing parts that meet functional, practical, and aesthetic requirements.

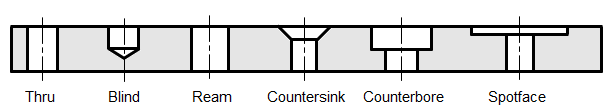

Overview of Different Hole Types

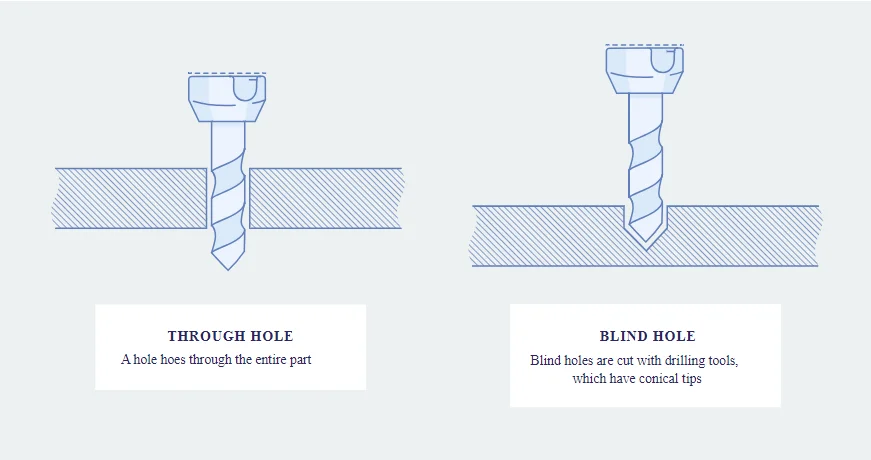

There are various types of holes, each with unique characteristics and applications. Two fundamental categories are blind holes and through holes. While through holes penetrate entirely through a part, blind holes are drilled or machined to a specific depth without fully exiting the material. Blind holes are strategically used when through holes are impractical or when a part requires internal features without compromising its external appearance or structural integrity.

Focus on Blind Holes and Their Relevance in Machining

Machining blind holes with limited depth has both advantages and challenges. This article explores the details of blind holes and their importance in enhancing primary reliability, reducing material waste, and providing designers and machinists with versatile options for part creation. Understanding the role of blind holes in machining is crucial for advancing design practices and ensuring efficient manufacturing processes.

Types of Holes in Machining:

To fully grasp blind holes, it is essential to recognize different hole types and their roles in machining.

- Blind Holes vs. Through Holes: Blind holes do not pass through the part, while through holes do. Understanding this distinction is vital for making informed choices during the design and machining phases.

- Role of Hole Types in Component Functionality: Holes, regardless of their type, impact a part’s usability. Through holes may be preferred for specific applications, such as providing a consistent path for bolts or improving ventilation. Conversely, blind holes offer advantages like enhanced strength and protection against environmental conditions. Analyzing how hole types contribute to a part’s overall functionality helps engineers make optimal design decisions.

- Considerations for Machining Different Hole Configurations: Machining processes vary depending on the type of hole being created. Machining blind holes involves specific considerations and challenges, including tool selection, processing time, and precision requirements.

Engineering Applications of Blind Holes

Purpose and Function

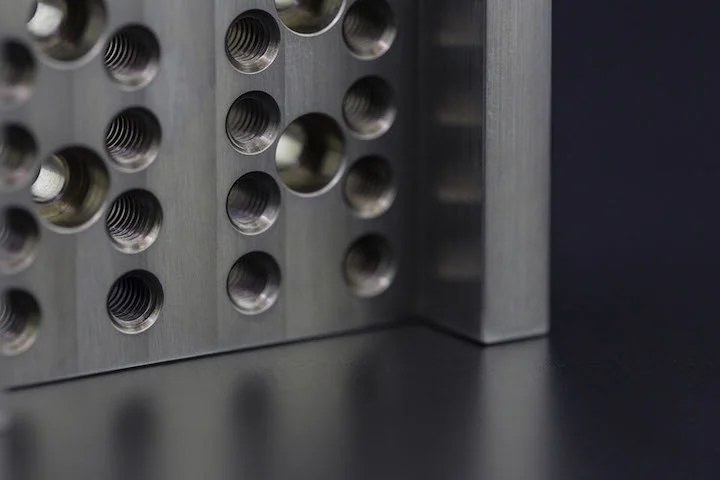

Blind holes are used in a wide range of applications across industries due to their unique benefits. A key role is enhancing part durability. By strategically placing blind holes, engineers can provide structural reinforcement without compromising overall weight. Additionally, blind holes are used in applications such as housing fasteners, press-fitting locating pins, or creating secure chambers for precision components.

Common Industries and Use Cases

Blind holes are widely utilized in various scenarios, including:

- Aerospace: Blind holes reduce overall weight without sacrificing the structural strength of aircraft components.

- Automotive: Engine blocks and transmission parts often incorporate blind holes to integrate accessories and minimize material usage.

- Electronics: Circuit boards may include blind holes to house connectors or securely mount components.

- Medical Devices: Blind holes help create clean, stable environments for sensitive medical instruments.

Understanding these applications is essential for professionals, designers, and machinists working across industries.

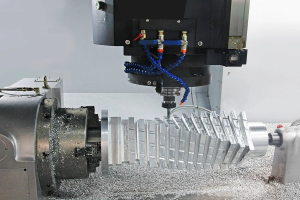

Machining Processes for Blind Holes

Drilling and Boring Techniques

Creating blind holes involves drilling and boring methods. Traditional drilling may suffice for simple blind holes, while complex geometries may require advanced techniques like gun drilling or trepanning. Processes such as line drilling and back drilling can achieve precise dimensions and smooth finishes in blind holes.

Challenges and Considerations

Machining blind holes is complex. Chip evacuation, tool selection, and the risk of tool deflection all impact the machining process. Addressing these challenges involves a combination of technological advancements, tool innovation, and optimized machining strategies.

Understanding the nuances of these processes is critical to ensuring the creation of accurate, high-quality parts for various design applications.

Design Considerations for Blind Holes

Designing parts with blind holes requires considering the following factors:

- Depth and Diameter: Determine the optimal hole geometry based on intended functionality and structural requirements.

- Material Properties: Understand how different materials respond to machining and how they influence blind hole design.

- Placement and Orientation: Strategically position blind holes to achieve functional goals without compromising the part’s overall integrity.

- Interaction with Other Features: How blind holes interact with other design elements, such as adjacent holes or surfaces.

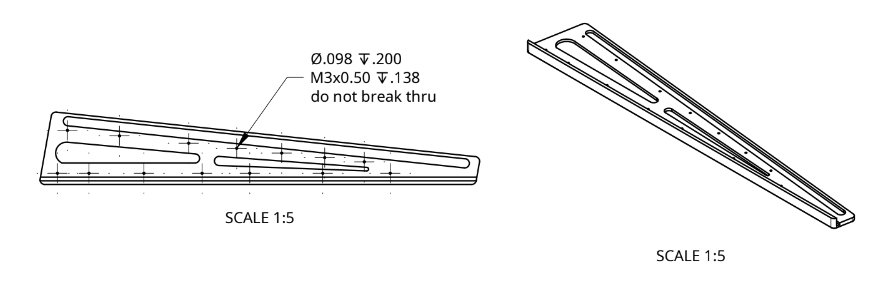

Example of Blind Hole Annotation on Engineering Drawings

The annotation ⌀.098 ↧.200 indicates a hole with a diameter of 0.098 inches and a depth of 0.200 inches.

Importance of Hole Placement and Orientation

The position and orientation of blind holes significantly affect a part’s functionality and manufacturability. Engineers must consider factors such as uniform stress distribution, ease of access for machining tools, and the overall aesthetics of the final product.

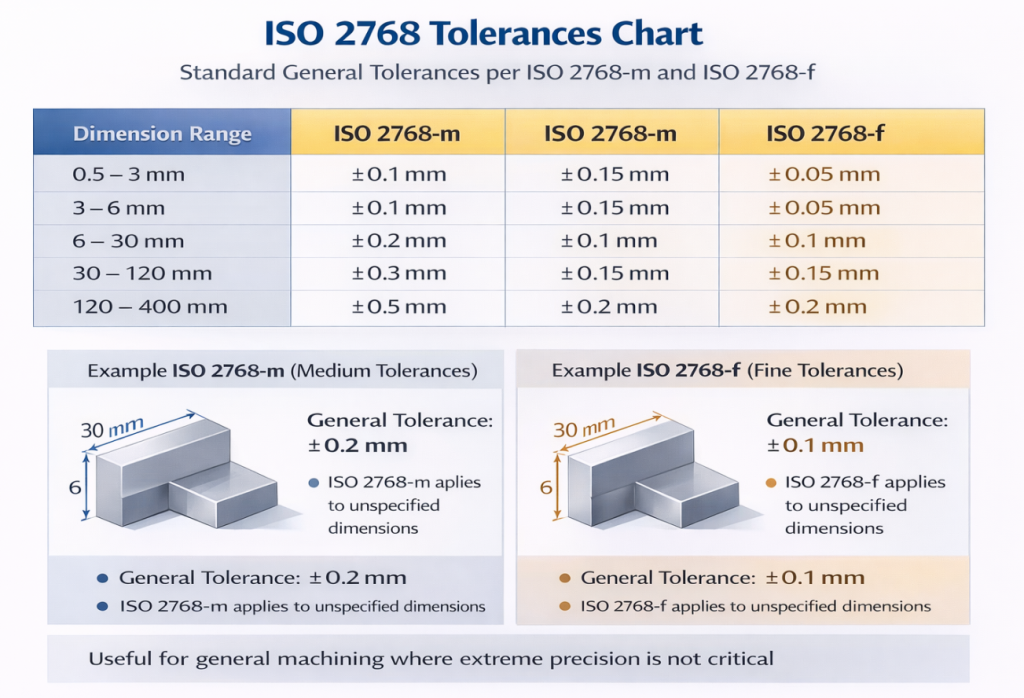

Tolerances, Surface Finish, and Material Considerations

Achieving precise tolerances and appropriate surface finishes is critical for blind hole design. Material properties, machinability, and intended applications influence tolerance decisions. The relationship between material characteristics, machining processes, and optimal surface finishes guides the pursuit of required precision in blind hole design.

Advantages and Disadvantages of Blind Holes

Benefits in Machining and Usage

- Enhanced Structural Integrity: Blind holes improve a part’s strength-to-weight ratio.

- Reduced Material Usage: Precisely designed blind holes minimize material consumption without compromising functionality.

- Sealed Chambers: Blind holes create enclosed spaces, protecting precision components from environmental degradation.

- Threaded Fastening: Blind holes provide secure locations for threaded fasteners, improving assembly efficiency.

Limitations and Challenges in Machining and Usage

- Machining Complexity: Producing blind holes, especially in intricate designs, can pose challenges with tool accessibility and chip removal.

- Potential for Stress Concentration: Poorly designed blind holes may lead to stress concentration, affecting the part’s structural integrity.

- Assembly Considerations: Blind holes can complicate assembly, particularly if strict tolerances are not maintained during machining.

Measurement and Inspection Techniques for Blind Holes

Quality Control Methods to Ensure Precision

Precision in blind hole machining is critical for part assembly and performance. Thus, accurate and precise measurement is essential, achieved through:

- Coordinate Measuring Machines (CMM): Measure hole dimensions and positional accuracy.

- Surface Profilometers: Evaluate surface integrity and perpendicularity.

- Non-Destructive Testing (NDT): Identify internal defects or inconsistencies.

- Metrology Tools and Inspection Processes: Specialized gauges, hole probes, and endoscopes, among others.

Understanding how these tools contribute to quality control in blind hole manufacturing is vital for maintaining consistent and accurate results.

Environmental Considerations

Impact of Blind Hole Machining on Sustainability

Blind hole machining has several sustainability implications, particularly regarding material waste. When designed correctly, blind holes reduce material usage, minimize waste, and improve the sustainability of assemblies.

Machining processes, including those for blind holes, often involve energy-intensive activities. Compared to other hole types, blind hole machining may reduce energy consumption. However, mechanical drilling can still contribute to higher energy usage in manufacturing.

Potential Advancements in Blind Hole Engineering

Blind holes are critical in engineering and machining, and their importance will grow with technological advancements.

One key trend shaping the future of blind hole machining is progress in materials and tools. Innovations in materials and tooling can enhance efficiency, precision, and flexibility in blind hole machining. Developments in tool coatings, material science, and manufacturing techniques may significantly impact the future of hole processing.

Another factor influencing blind hole machining is compliance with industry regulations. Adhering to global standards and specifications facilitates smoother collaboration among manufacturers and promotes global trade. It also ensures products meet consistent quality standards, regardless of their origin.

Ensuring Proper Blind Hole Machining

Training programs for machinists and engineers are essential for developing proficiency in blind hole machining. Formal education, on-the-job training, and continuous professional development can help individuals stay updated on the latest advancements and best practices.

Collaboration between engineers, designers, and machinists significantly impacts the success of blind hole machining projects. An interdisciplinary approach to hole design and machining can drive innovation and optimize blind hole designs. Case studies highlighting successful collaborative efforts provide insights into challenges faced, collaborative methods used, and their impact on results.

In conclusion, the importance of blind holes in engineering and machining cannot be overstated. They play a crucial role in enhancing part durability, reducing material waste, and offering versatile options for designers and machinists. As technology advances, continuous exploration and innovation in blind hole machining are necessary to ensure they remain efficient, lightweight, and structurally sound. For more information, contact us at Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.