Extrusion and injection molding are two primary methods for manufacturing plastic and rubber parts. Extrusion shapes continuous profiles by pushing material through a die, producing uniform cross-sectional shapes ideal for pipes, tubes, and weatherstripping. Injection molding, on the other hand, injects molten material into a mold cavity to create complex 3D parts, suitable for applications requiring design complexity and precise tolerances.

This article examines extrusion and injection molding in detail to help determine the better choice for your project. It compares the processes in terms of cost, scalability, complexity, and efficiency, and includes information on advanced considerations, applications, and trends.

What Is Extrusion Molding?

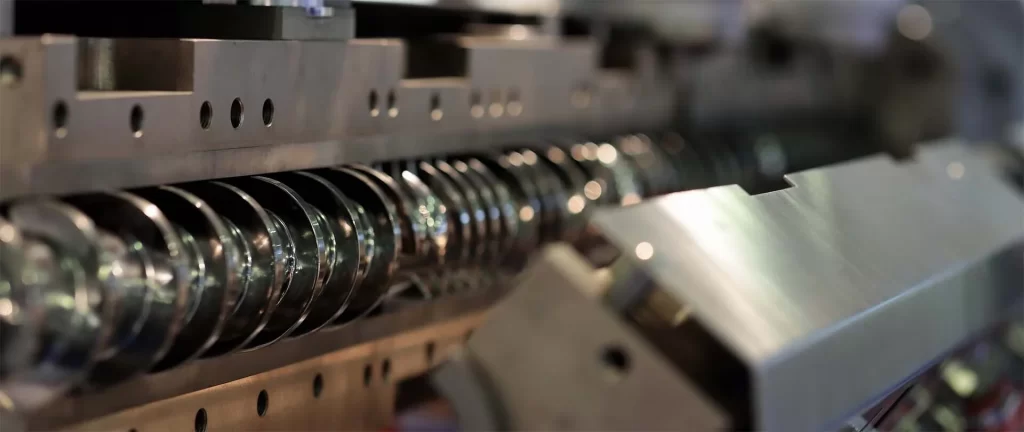

Extrusion is a proven process for molding continuous lengths of plastic or rubber into uniform cross-sectional shapes. These profiles can be as simple as tubes or ropes, or more complex—for example, door and window seals shaped like letters (D, E, J, P, U). Extruded profiles are typically cut to length or into individual parts.

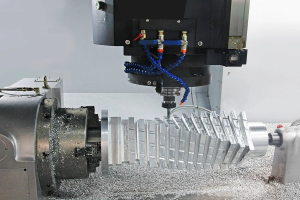

Extruders produce solid, semi-hollow, or hollow profiles with smooth surface finishes. The process begins with feeding plastic or rubber into a hopper. Hot extrusion heats polymers above their recrystallization temperature, while cold extrusion occurs at room temperature. A screw conveys the material, which is then forced through a machined metal die under high pressure to achieve the desired shape.

Process Optimization for Industrial Applications

Optimizing extrusion involves balancing material flow, cooling rates (for hot extrusion), and production speed—yielding higher quality, efficiency, and less waste. Best practices and innovations further enhance quality:

- Material Optimization: Well-designed dies ensure uniform material flow across the profile. Feed rate control, proper screw compression ratios, and flight geometry (matching material properties) are critical. Adjusting back pressure and screw speed stabilizes melt pressure, ensuring consistent output without degradation.

- Cooling Rate Optimization: Hot extrusion uses water baths (rapid cooling) or air systems (gradual cooling). For hollow profiles, internal air/fluid systems cool inner and outer surfaces evenly. Infrared thermography and embedded sensors enable real-time monitoring.

- Production Speed Optimization: Higher screw speeds boost output but may cause inconsistent flow. Many extruders now use feedback systems to auto-adjust screw speed based on melt pressure, ensuring stability. High-volume production may require hot extrusion equipment for fast polymer melting.

Material Considerations in Extrusion

Beyond melt parameters, key factors include:

- Plastics: Cool and solidify at varying rates; some shrink more than others. Thermoplastics soften when heated and solidify when cooled; thermosets cannot be remelted or re-extruded.

- Rubbers: Require vulcanization (curing) to achieve final properties. Rubber may expand after exiting the die, but optimized die design and parameters mitigate dimensional changes.

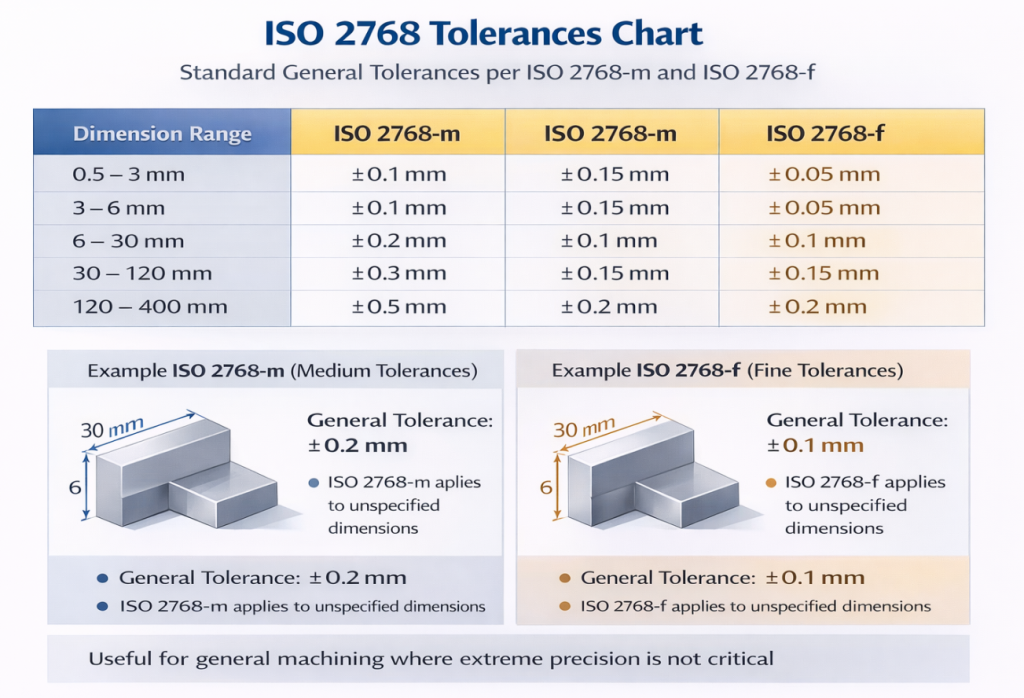

Extrusion supports diverse polymers: engineering thermoplastics, thermoplastic elastomers (TPEs), and high-performance materials like PEEK. Note that extruded part tolerances are less precise than machined metal parts, due to tooling and material shrinkage.

High-Volume Applications

Extrusion is widely used in high-volume production:

- Automotive: Windshield wipers, weatherstripping.

- Construction: Pipes, tubing, fencing, railings, window frames, sheets.

- Aerospace: Insulation for wires/cables in aircraft cabins.

- Medical: Tubing, catheters.

Advantages and Limitations

- Advantages: Low per-part cost, support for continuous production, high efficiency, good surface finishes.

- Limitations: High initial setup costs, potential dimensional variation in final products, restricted to single cross-sectional shapes per run.

What Is Injection Molding?

Injection molding starts with loading plastic resin pellets (or mixing liquid rubber) into a hopper. The material is heated in a barrel until molten, then injected under pressure into a mold cavity. The melt solidifies into the mold’s shape (typically machined from aluminum or steel) before the part is ejected.

Injection molding produces solid parts (not hollow) but supports significant design complexity. Depending on mold quality, parts can achieve tight tolerances. It can also create textured surfaces or features like logos.

Process Efficiency and Complexity Management

Efficiency and complexity management are key to optimizing production:

- Efficiency: Involves cycle time reduction, material waste minimization, machine performance monitoring, and automation (e.g., closed-loop control, real-time monitoring).

- Complexity Management: Includes mold design optimization, controlling part variability, and simplifying processes/materials. Quick mold change systems and flexible workcells reduce downtime.

Injection molding benefits from simulation software (mold flow analysis, cooling optimization), Industry 4.0/IoT integration (smart manufacturing, machine learning for process control), and ERP integration (production scheduling, supply chain management).

Material Integration for Advanced Applications

Injection molding supports high-performance polymers (e.g., PEEK), composites (e.g., glass-filled nylon), engineering plastics (e.g., polycarbonate), and elastomers (e.g., liquid silicone rubber for medical/aerospace parts).

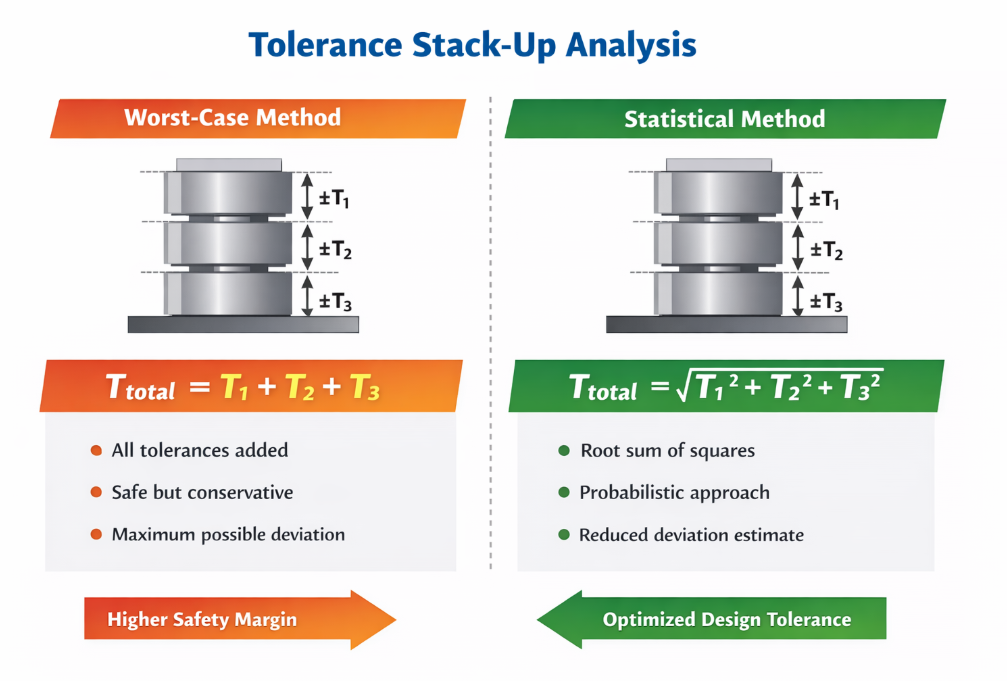

Precision and Tolerance Control

Injection molding maintains precise dimensions and tight tolerances in high-volume production, making it ideal for demanding applications. Designers must account for tolerance stack-up to ensure assembled parts fit together.

Advantages and Limitations

- Advantages: Supports complex designs (per guidelines like Debaolong Seiko’s free downloadable injection molding design guide), maintains tight tolerances, and offers cost-effective high-volume production with hardened steel molds.

- Limitations: Higher mold costs (offset by high volumes). For prototyping/low volumes, soft or semi-hardened steel molds suffice. Master Unit Die (MUD) inserts reduce costs via interchangeable components in a universal frame.

Key Differences Between Extrusion and Injection Molding

| Factor | Injection Molding | Extrusion |

|---|---|---|

| Part Geometry | Complex 3D shapes with intricate features | Simple, uniform cross-sectional shapes |

| Surface Details | Fine details, textures, logos, variable wall thickness | Limited details, uniform thickness |

| Multi-Material Parts | Overmolding or two-shot processes | Co-extrusion (layered), but not mixed materials |

| Part Size | Small to large, light to heavy | Best for long, continuous parts (width/height limited by die) |

| Customization | Highly customizable with complex features | Less customizable; requires secondary processes for complexity |

| Material Options | Wide range, including multi-material integration | More limited, but layered structures possible |

Cost and ROI

- Extrusion: Lower mold costs (simpler dies) and faster ROI for high-volume, simple parts.

- Injection Molding: Higher initial mold costs, but amortized over high volumes of complex parts. Production costs are generally higher than extrusion, though optimized cooling systems can reduce cycle times (at added cost).

Production Scalability

- Extrusion: Easily scales from low to high volumes due to low tooling costs and simple setup.

- Injection Molding: Scalable but may require tooling upgrades (e.g., soft steel molds for low volumes vs. hardened steel for high volumes).

Part Complexity and Design Flexibility

- Injection Molding: Excels at 3D parts with ribs, bosses, snap-fits, and complex cavities. Integrates features like threads and hinges directly.

- Extrusion: Limited to uniform cross-sections. Secondary processes add 3D features or internal cavities.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.