Metal 3D printing encompasses various additive manufacturing processes: Directed Energy Deposition (DED), Binder Jetting, and Direct Metal Laser Sintering (DMLS). We will focus on these processes for comparison.

The differences between casting and DMLS are quite distinct, so depending on your application, choosing the most suitable option may be a straightforward decision. Three primary factors will drive your choice: part design, quantity, and lead time.

Fundamentals of Metal 3D Printing and Traditional Casting

First, here is a baseline understanding of how these two processes work. In casting, molten metal (or plastic) is poured into a mold that contains a cavity reflecting the shape of the final part. Over time, the material cools and solidifies. Once the part hardens, the mold is removed, and the part (casting) is ready for any necessary finishing options. This is a rather lengthy process, so be prepared to wait for your parts. More details will follow later.

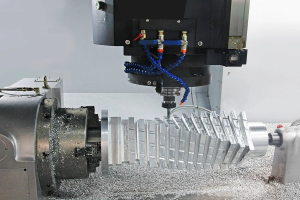

In contrast, metal 3D printing builds your part layer by layer using a bucket of metal powder. Once a layer is completed, the build platform descends into the bucket, and a new layer of metal powder is recoated on the surface for the next pass. It uses a powerful laser to melt and fuse the powder, growing the part. Although manufacturing parts (especially large ones) takes time, these 3D-printed parts are as strong as cast parts, with a density approaching 100%.

Part Geometry for Casting and Metal 3D Printing

Three design-centric issues define some differences between the two manufacturing methods: part complexity, precision, and part size.

Part Complexity

If your part has a simple geometry and does not require additional finishing, you can use casting and (eventually) simply remove the part from the mold. However, parts with complex geometries, intricate designs, and small features may be better suited for 3D printing. The primary reason for this is that in casting, it is difficult to get the liquid material to flow through the small features built into the mold, resulting in incomplete parts. Meanwhile, 3D printing excels at building small features and then performing post-printing remedial work to remove the support structures needed to start the build.

Both processes require designs with uniform wall thickness and radii. Parts with these design qualities will cool more consistently, shrink less, have higher dimensional accuracy, and possess enhanced mechanical properties. Consistent wall thickness also allows for more efficient use of materials, thereby saving costs.

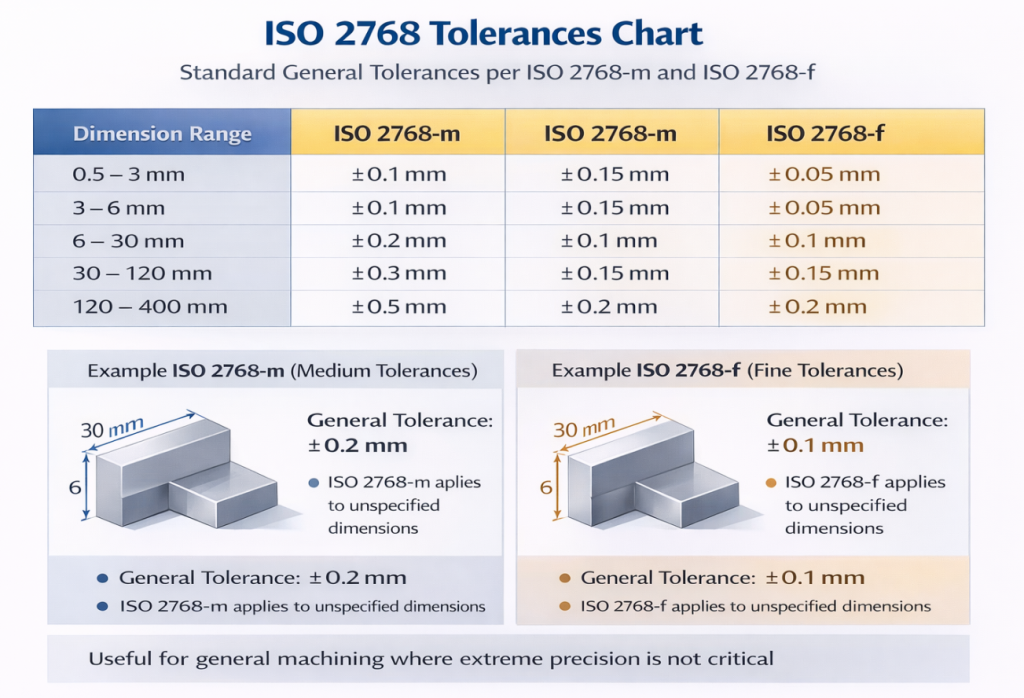

Accuracy

The ability of metal 3D printing to create small features makes it a better choice for detailed part designs. Casting can produce parts with tight tolerances and good surface finishes. However, complex castings that need to be assembled usually require being made in pieces and brazed together. This extra step opens the door to potential inaccuracies and inconsistencies during the joining process. These parts also shrink as they cool, increasing imprecision. Casting accuracy is also affected by the material itself and the temperature of the material when poured into the mold.

Working with a digital additive manufacturer allows you to receive Design for Manufacturability (DFM) feedback when submitting your CAD model. Automated processes provide instant feedback on your parts and offer a “first pass” to determine if the part is suitable for metal 3D printing. It also reminds you that just because something can be 3D printed in metal does not mean you should do it.

Part Size

Although our largest metal printers can 制造 parts as large as 31.5 inches x 15.7 inches x 19.7 inches (400mm x 800mm x 500mm), casting may be a more feasible option for larger parts. That said, new printers and metal printing technologies emerge every year, pushing the boundaries of this limit.

Quantity Considerations: Casting vs. Metal 3D Printing

Metal 3D printing excels at manufacturing small batches of end-use parts. Printing large parts does take time, but batch printing smaller parts simultaneously can speed up production time. Since no tooling is required, validation runs can be done on a faster timeline. If you need parts at a production level, casting is typically the first choice, but if you only need a small number of parts, it does not make much sense to spend the time and money to create a mold (and wait for the foundry to be available).

Lead Time: Casting vs. Metal 3D Printing

Need parts now? In this case, casting is certainly not the best solution, especially for low volumes. Due to foundry capacity issues and the time required to 制造 molds, cast parts can take over a year. This is even if you have existing molds available. With casting, if you accidentally lose or damage a mold or need to adjust the design, you are back to square one. Printed metal parts can be in your hands in days. Larger parts may require a considerable printing time, but it still may outpace the lead time for cast parts.

Applications of Metal 3D Printed Parts vs. Cast Parts

Typically, casting is used to produce very large parts for transportation (rail, marine, etc.), construction, machinery, and some consumer goods. These parts tend to be larger and often thicker. Some examples include engine blocks, bridge components, marine propellers, and turbine blades. These usually do not require a lot of detailed work, so casting is ideal.

While metal 3D printing can be used to produce large parts (as mentioned above), it excels at rendering complex geometries, prototyping with production-grade materials, creating functional end-use parts, and even allowing you to combine parts that would otherwise need to be assembled. Typically, if no mold is available, it can deliver parts faster than casting, even if the parts have many details.

Quick Comparison

Here is an overview comparison of the two manufacturing methods:

| Feature | Casting | Metal 3D Printing |

|---|---|---|

| Lead Time | Very long (may exceed one year), even with existing molds | A few days for medium-sized parts |

| Production Availability | Limited number of foundries, with long lead times for booking | Printer capacity can be increased, and technology is improving |

| Part Changes | Your tooling may become obsolete | Design changes can be made immediately to printed parts and uploaded |

| Startup Costs | High mold production costs | Zero |

| Part Cost | High for small quantities but decreases as quantity increases | Lower (no tooling required) but decreases less for high-volume production |

| Material Selection | Wider range of options | Limited list, but growing, currently including most major metal choices |

Conclusion

According to a recent issue of Additive Manufacturing magazine, while additive manufacturers can always add additional capacity and technology is constantly improving, the number of foundries, especially in the United States, has stagnated. Adding foundries is a considerable undertaking, with high costs and time requirements that are prohibitive for most companies and investors.

Interestingly, some companies are using both technologies. Metal molds can be manufactured via 3D printing and then used for casting, but you must ensure the design is suitable for the casting environment.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.