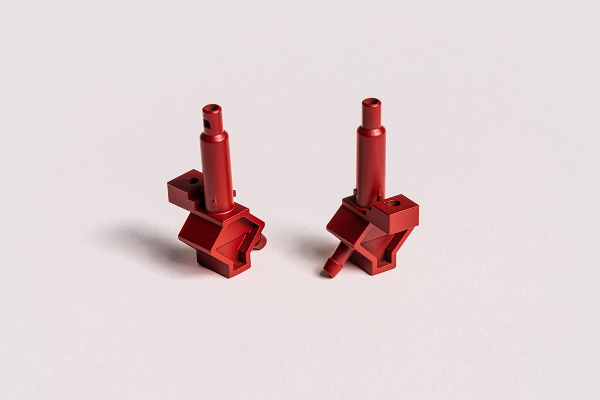

Cerakote is a versatile ceramic-based coating that serves as an excellent finishing option for many 3D-printed parts. It checks numerous boxes that contribute to the durability of your parts and offers a wide range of color and other aesthetic choices. Additionally, it complies with REACH, ROHS, and Prop. 65 standards.

Applying Cerakote is essentially the same as applying any other coating or paint. Our certified Cerakote applicators mix the coating in a specialized professional spray booth and apply it using a spray gun. This certification ensures that your application will meet the highest specifications when using Cerakote.

As certified applicators, we can apply the full range of Cerakote offerings. It can also be applied to any finish level. For example, if you need a coating for functional purposes and don’t necessarily require a fully customized surface treatment, the coating can be applied to standard finished parts. This applies to a variety of technologies and materials.

Cerakote Material Properties

- Durability: As a ceramic, Cerakote is an extremely durable coating, featuring wear resistance, abrasion resistance, and scratch resistance. It is an excellent choice when your parts will be exposed to harsh environments.

- Chemical Resistance: When applied properly, Cerakote finishes are largely unaffected by solvents, acids, and alkalis.

- Corrosion Resistance: Similar to its chemical resistance, Cerakote coatings hold up well when exposed to chemicals, saltwater, and other corrosive substances.

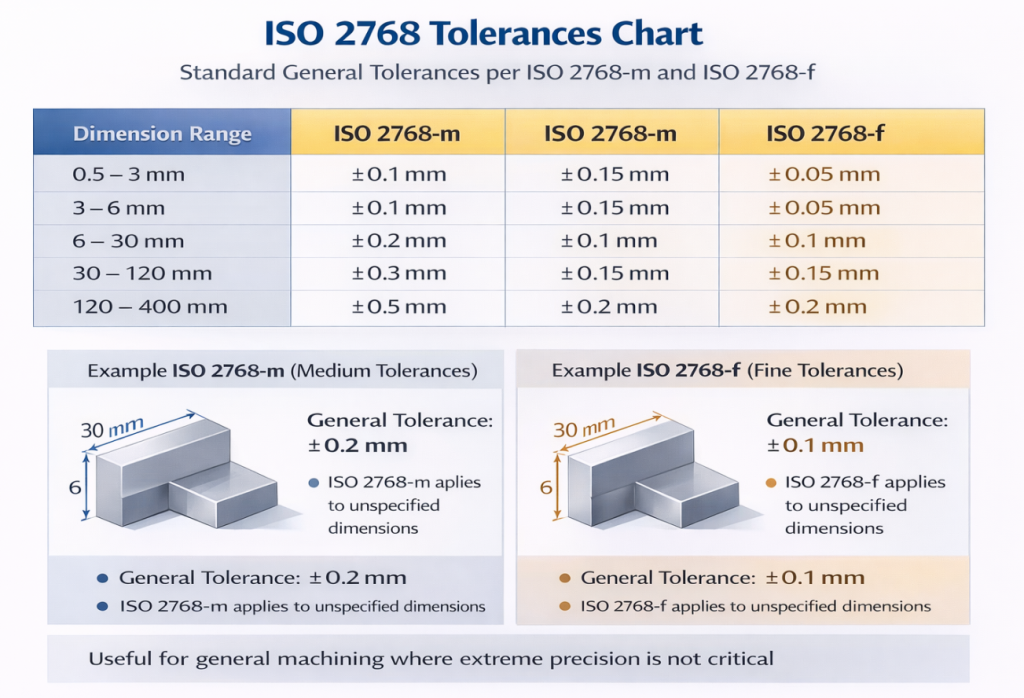

- Thin Coating: A typical Cerakote application adds minimal thickness to your parts. If you’re developing precision parts or are concerned about tight tolerances, this finish will keep your parts within specifications.

- UV Stability: When you finish your parts with Cerakote, exposure to ultraviolet (UV) light is not a problem. Some applications offer 100% UV stability.

- Multiple Colors and Finishes: Cerakote is also highly regarded for providing excellent aesthetic options. We offer dozens of colors. If the gloss of the coating is a concern, note that it depends on the color you choose—some shades are available in gloss, matte, and satin finishes.

- Versatility: Whether your parts are printed from plastic, polymer, or metal, Cerakote is an excellent finishing option for most parts.

Coating Types and Use Cases

We can apply different types of Cerakote finishes. The first step involves selecting the series that best suits your situation. We offer the following series: C, F, H, Elite, and Glacier. Here’s a quick comparison of the advantages of each:

| Series | Corrosion Resistance | Durability/Hardness | UV Stability | Chemical Resistance | Thermal Stability |

|---|---|---|---|---|---|

| C | Good | Very Good | Very Good | Very Good | Very Good |

| F | Very Good | Very Good | Good | Very Good | Very Good |

| H | Very Good | Very Good | Good | Very Good | Very Good |

| Elite | Very Good | Very Good | Good | Very Good | Very Good |

| Glacier | Good | Good | Very Good | Very Good | Very Good |

Common Applications of Cerakote Finishes

It’s highly likely that companies in your industry are already using Cerakote as a finish. The robust, lightweight, and thin ceramic coating is popular in a wide range of applications. The most common industries using it include:

- Aerospace: To withstand extreme temperatures, pressures, and vibrations, everything on your parts must be extremely strong and able to endure these environments—and Cerakote excels in this regard.

- Automotive: Engine components must handle a wide range of temperatures. They also have to endure rain, snow, road salt, and abrasives. This is why you often see Cerakote finishes on automotive parts.

- Aesthetic Finishes: Cerakote looks great, regardless of the series or color you choose. Compared to other aesthetic coatings like anodizing, Cerakote offers a much broader range of colors. It provides matte, satin, or gloss finishes that appear uniform and consistent. Most importantly, the combination of colors and finishes gives you numerous options to precisely achieve the look you desire.

- Military and Defense: These applications require extremely high durability, withstanding extreme temperatures, preventing corrosion, and avoiding scratches and wear.

If you want to learn more about how Cerakote finishes can help improve your 3D-printed parts, for more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.