It is well-known that the surface of an object is crucial. Improper maintenance can lead to issues such as oxidation, corrosion, and fatigue failure. To avoid surface problems, we use surface treatment technologies. Both powder coating and galvanizing fall under surface treatment techniques. This article will provide a comprehensive guide to powder coating and galvanizing, covering all aspects such as suitable materials and applications.

What Is Powder Coating?

Let’s use an example to explain powder coating. Take a screwdriver: its handle is usually covered with rubber. The process of applying this rubber coating to the handle is called powder coating. In other words, it is a manufacturing process where a layer of coating material is applied over a base material. This coating enhances durability and grip.

What Is Secondary Molding?

Working Principle of Secondary Molding

The process consists of 4 simple steps:

- Prepare the mold

- Form the first layer on it

- Apply the second coating layer

- Cool and perform the required finishing steps

Main Types of Powder Coating Processes

This section will familiarize you with different types of powder coating processes.

Injection Powder Coating

In this method, you coat a pre-formed base material, meaning the second layer is deposited onto an already coated material. This method is suitable for mass production. One of the most common examples is smartphone cases with TPU edges.

Two-Component Molding

You could call it dual-color injection molding, and this technology is most widely used in Germany. Two different materials are injected into a single machine in sequence to produce a single product. This technique is ideal for keyboard keys.

2K Molding vs. Powder Coating

The table below summarizes the differences between 2K molding and powder coating:

| Aspect | Two-Component Molding | Traditional Powder Coating |

|---|---|---|

| Speed | Faster (one cycle) | Slower (two cycles) |

| Cost | Higher machine cost | Lower mold cost |

| Bonding Strength | Excellent | Suitable for surface treatment |

Insert Molding

The pre-fabricated part is called an insert. The insert is placed into the mold cavity, and then the molding material is added. It is used in consumer goods and surgical components.

Powder Coating vs. Insert Molding

You can explore the core differences between powder coating and insert molding:

| Aspect | Powder Coating | Insert Molding |

|---|---|---|

| Process | Layered materials | Wrapping pre-placed inserts |

| Bonding Strength | Chemical adhesion | Mechanical encapsulation |

| Best For | Soft grips, multi-material parts | Metal/plastic hybrids |

| Cost | More advanced tools | Suitable for simple components |

Polyurethane Casting

As the name suggests, “casting” involves adding liquid material into a mold of the desired shape. You can use this process for prototyping or small-batch production. Common applications include medical handles and seals.

Fabric and Mesh Powder Coating

You can integrate woven or fabric materials with plastic during the molding process. Common applications include sports equipment and footwear. This process enhances the functionality and durability of products.

Materials Used in Powder Coating

This part of the article contains information about the materials used in the powder coating process.

Common Thermoplastics for Powder Coating

We use thermoplastics for powder coating because of their fluidity and low melting points.

TPE (Thermoplastic Elastomer)

TPE is a block copolymer that melts like plastic but bends like rubber. Due to its softness and flexibility, it is often used in manufacturing tool handles and seals.

TPU (Thermoplastic Polyurethane)

It is a polyurethane member of the TPE family, featuring high strength and wear resistance. This material has good abrasion resistance, so it is commonly used in making phone cases and cables.

PVC (Polyvinyl Chloride)

PVC is a versatile vinyl plastic. We choose this material for powder coating because it is economical and durable. Its applications include pipes and medical catheters.

Powder Coating Plastic onto Metal

Plastic and metal are two different materials with distinct properties. Therefore, combining plastic and metal results in a hybrid material.

Advantages of Metal Substrates in Powder Coating

The advantages of metal substrates are as follows:

- Enhanced strength and durability due to increased impact strength.

- Metal dissipates heat better than plastic and is harder, so it is less likely to deform.

- Well-treated metal forms stronger chemical bonds with plastic, thus reducing the risk of delamination.

Types of Metals Suitable for Powder Coating

The table below provides different materials (usually used as inserts) suitable for the powder coating process:

| Metal | Key Properties | Common Applications |

|---|---|---|

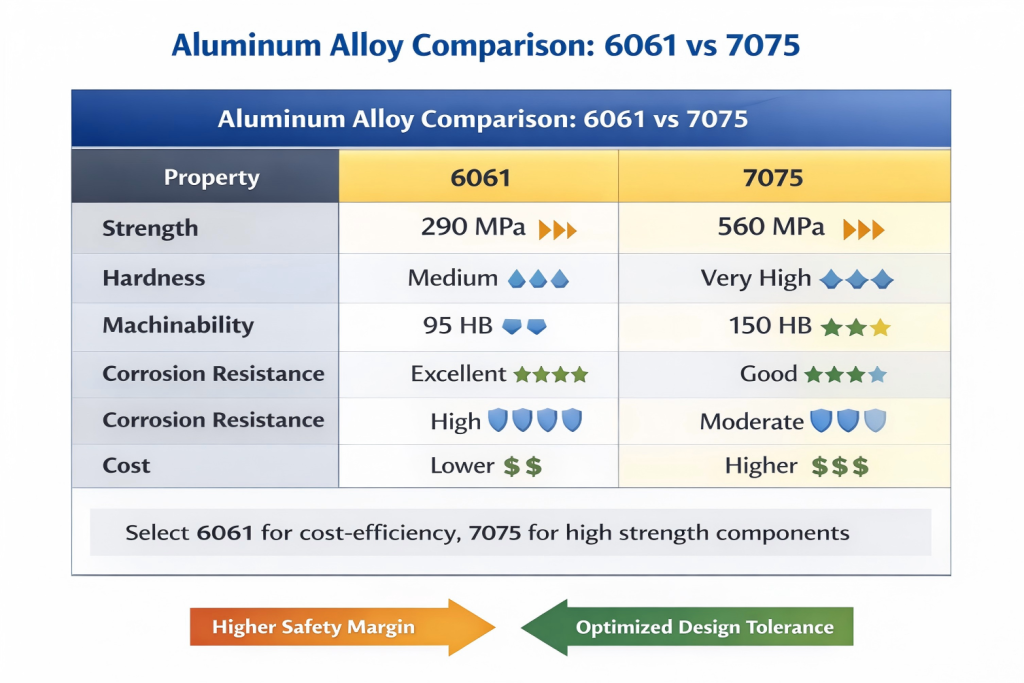

| Aluminum 6061 | Lightweight, corrosion-resistant | Aerospace, automotive parts |

| Stainless Steel | High strength, sterilizable | Medical devices, food industry |

| Brass | Excellent conductivity, machinability | Electrical connectors, valves |

| Titanium | Biocompatible, high strength-to-weight ratio | Surgical implants, sports equipment |

Types of Metals Unsuitable for Powder Coating

Here are the reasons why these materials cannot be used for powder coating:

| Metal | Reasons for Unsuitability |

|---|---|

| Zinc | Low melting point may cause warping during molding. |

| Magnesium | Reacts with many plastics, which can corrode or weaken adhesion. |

| Lead | Toxic and incompatible with food/medical applications. |

| Untreated Steel | Prone to rust; requires electroplating or coating for adhesion. |

Advantages of Powder Coating

If you adopt the powder coating manufacturing process, you will gain the following advantages:

Functional Advantages

Powder coating offers the following functional benefits:

- Excellent durability and weather resistance

- Built-in impact, vibration, and stress suppression

Aesthetic Advantages

We often use powder coating to achieve aesthetic effects:

- High-quality appearance, feel, and custom branding

Production Advantages

Powder coating also has some production-related advantages, as you can see from the following points:

- Fewer assembly steps and faster production speed

- Reduced total cost of parts and tools

Applications of Powder Coating in Various Industries

Now, we will discuss common applications of powder coating in well-known industries:

- In the automotive industry, you can use PC+TPU materials for powder coating to make gear shift knobs.

- In the electronics industry, we use ABS+TPE to powder coat drone controllers.

- In the medical industry, we use PEEL + LSR materials in powder coating to make ergonomic scalpel handles.

What Is Galvanizing?

Galvanizing is the process of depositing a layer of molten zinc on the surface of a metal to prevent corrosion under normal conditions. The most common application of galvanizing is road guardrails.

Hot-Dip Galvanizing vs. Electrogalvanizing – How They Differ

Hot-Dip Galvanizing

If the base material is immersed in molten zinc, and a layer of zinc is deposited on the base material, it is called hot-dip galvanizing. Hot-dip galvanizing is used to deposit a thicker zinc layer on the base material.

Electrogalvanizing

If you want a thin, smooth zinc layer, electrogalvanizing should be used. The zinc layer is deposited through electrodeposition.

Formation of Zinc Layer and Self-Healing Effect

You will be surprised to find that the zinc layer is actually a self-healing layer. At the scratch, zinc reacts with oxygen to re-form a protective layer.

Most Commonly Galvanized Metals

These are the most commonly galvanized metals:

- Mild steel: Used in construction, road side guardrails, etc.

- Cast iron: Mainly used in heavy-duty applications.

Powder-Coated Steel vs. Galvanized Steel: Key Performance Factors

This section provides brief but informative data on how powder coating differs from galvanizing.

Corrosion Resistance and Outdoor Lifespan

Galvanizing

Due to the self-healing ability of the zinc layer, it can last for decades but is not suitable for harsh conditions. This means you can safely use it for long-term applications.

Powder Coating

Mainly used in high-temperature environments, resistant to oxidation, etc., and can be easily used for 14-15 years.

Salt Spray Test Duration and Actual Service Life

In practical applications, galvanized steel has salt resistance for over 100 hours, while powder coating has salt resistance for 600-1000 hours.

Mechanical Durability

The table below shows that galvanized steel performs best in impact-resistant applications, while powder coating is used for aesthetic purposes only.

| Factor | Powder Coating | Galvanized Steel |

|---|---|---|

| Impact Resistance | Moderate – may chip or crack under heavy pressure. | High – zinc layer absorbs impact, reducing dent risk. |

| Scratch Resistance | Low to moderate – scratches occur but can be repaired. | Moderate – zinc scratches but “self-repairs” through oxidation. |

| Wear Resistance | Good – durable but wears faster than galvanizing. | Excellent – zinc layer resists friction better. |

Appearance and Color Options

Powder coating can come in any color you want, while galvanizing presents a silver-gray color.

Texture, Gloss, and Patina Potential

If you want design flexibility, choose powder coating, as patina limits the color and aesthetics of the design.

| Aspect | Powder Coating | Galvanized Steel |

|---|---|---|

| Texture | Smooth or custom textures | Naturally rough/flakey |

| Gloss | Fully customizable (matte to glossy) | Fixed metallic sheen |

| Aging | Color remains stable | Develops white patina over time |

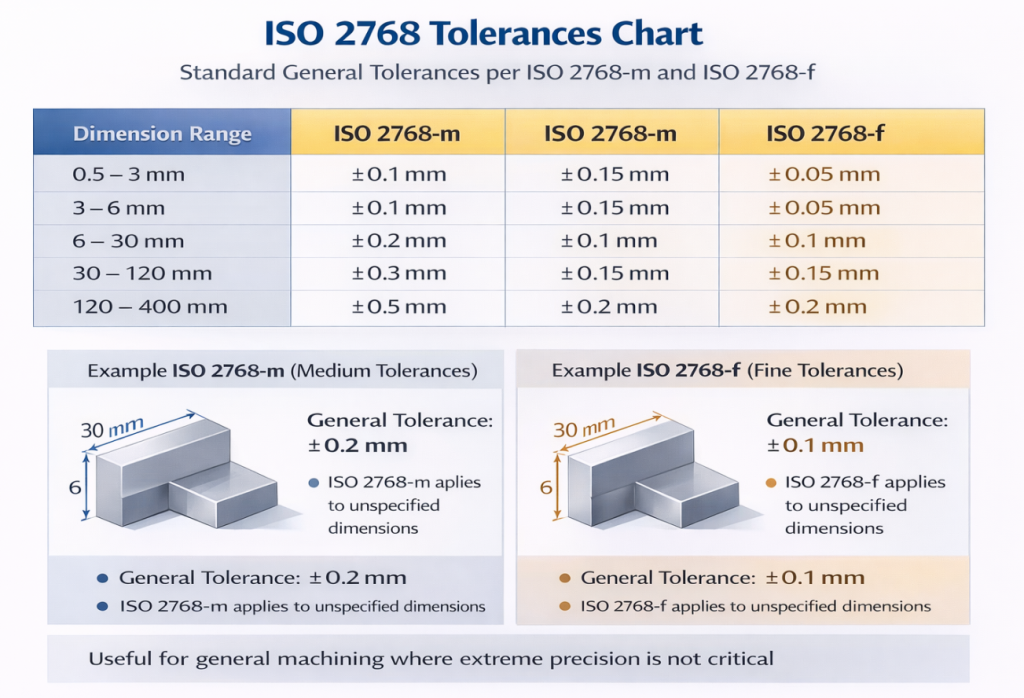

Thickness, Tolerances, and Risk of Part Distortion

The table below summarizes information on these factors:

| Factor | Powder Coating | Galvanized Steel |

|---|---|---|

| Thickness | 2-10 mils (50-250μm) | 3-8 mils (75-200μm) |

| Tolerances | Maintains tight tolerances | May affect tight tolerances |

| Distortion Risk | Minimal | Moderate |

Cost Analysis Over Product Lifespan

Initial Treatment Costs

Initial costs indicate that powder coating is cheaper than galvanizing for small-batch production.

| Cost Factor | Powder Coating | Galvanizing |

|---|---|---|

| Preparation | $5–15/sq ft (cleaning, sandblasting) | $2–8/sq ft (degreasing, pickling) |

| Equipment | $50k–200k (spray booths, ovens) | $10k+ (zinc baths, cranes) |

| Labor | $20–50/hour (skilled technicians) | $15–30/hour (less specialized) |

Maintenance and Recoating Expenses

Galvanizing has lower maintenance costs due to its self-healing properties. The recoating cost of powder coating is lower than that of galvanizing.

Hidden Costs

Some hidden costs include transportation, masking, rework, and downtime. These costs are considered of secondary importance in cost analysis.

Environmental and Safety Considerations

VOC-Free Powder vs. Molten Zinc Fume Control

Powder coating does not produce volatile organic carcinogens, but galvanizing produces zinc fumes, which can cause lung irritation.

Energy Consumption and Carbon Footprint

Compared to powder coating, the galvanizing process consumes more energy. The carbon footprint of galvanizing is 3 times that of powder coating.

Best Applications for Powder Coating vs. Galvanized Steel Surface Treatments

Advantages of Galvanizing

For outdoor applications such as utility poles and guardrails, you should choose galvanizing because of its high corrosion resistance.

Highlights of Powder Coating

In applications such as building panels or electric vehicle frames, where an attractive appearance is required, powder coating is your first choice.

Combined Systems

Many applications use a combined system of powder coating and galvanizing, such as bridges, marine equipment, etc.

Pros and Cons of Powder Coating vs. Galvanized Steel

Advantages of Powder-Coated Galvanized Steel

You will get excellent corrosion resistance and aesthetics. Strength will also be improved.

Issues with Powder-Coated Galvanized Steel

- Adhesion problems

- Risk of hydrogen embrittlement

- Thermal stress mismatch

Decision Checklist: How to Choose the Right Finish

Climate and Exposure Conditions

If conditions are harsh or exposed to normal rain, etc., then galvanizing will perform perfectly in such situations.

Aesthetic and Brand Requirements

If you need the product to be aesthetically pleasing, do not hesitate to choose powder coating.

Regulatory or Industry Standards

Here are some standards covering galvanizing and powder coating respectively:

- ASTM A123: For hot-dip galvanizing; provides information related to thickness, adhesion, and appearance.

- AAMA 2605: For powder coating; guides salt resistance, color retention, and chalk resistance.

Conclusion

We conclude that both powder coating and galvanizing are surface treatment methods used to improve surface durability. Galvanizing helps improve corrosion resistance, while powder coating excels in design flexibility and aesthetics. If you want to choose the right surface treatment for your custom project, Debaolong Seiko is a great choice! For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.t surface treatment for your custom project, Debaolong Seiko is a great choice!