Both climb milling and conventional milling are machining and cutting methods. Initially, conventional milling was a common processing method, that is, it is an ancient method. Climb milling can be said to be an advanced form of milling processing. After reading this article, you will fully understand the differences between these methods, their inventions, how they are used, etc.

What is Climb Milling?

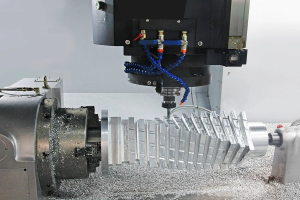

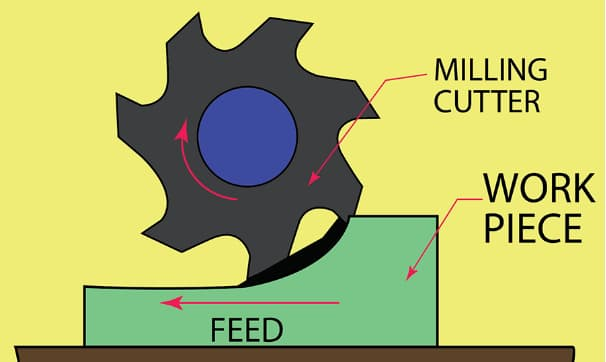

A processing method is applied through CNC machine tools. As its name suggests, the teeth of the cutting tool climb over the material surface to cut the material and convert it into the desired shape. Thanks to the support of CNC machine tools, this is a simple process. The cutting tool operates in the direction of the workpiece movement. The following figure will help you understand the work more accurately.

Direction of Climb Milling

As shown in the figure in the introduction part, the milling cutter processes in the feed direction (i.e., the direction of the workpiece). The milling cutter remains in contact with the workpiece.

Climb Milling in CNC Machine Tools

Anyone who has direct or indirect contact with CNC machine tools knows that CNC machine tools have many functions. These functions are very advanced, such as the automatic tool change mechanism, which can easily perform climb milling. Due to CNC machining, climb milling can provide high-precision and precise tools, which are further used in critical industries such as aerospace, automotive, and medical.

What is Conventional Milling?

Climb milling is just an advanced version of this milling method. It is the oldest milling method, using manual tools to make complex designs, etc. It is also known as the up milling process because the cutting tool operates in the opposite direction of the workpiece movement.

Working Principle of Conventional Milling

You can understand how it works from the following figure.

To produce the desired shape, you need to push the cutting tool in the opposite direction to the workpiece movement.

Conventional Milling Machines and Their Applications

The following are the applications of conventional milling:

- Preparing complex and curved components

- Achieving a smoother surface finish

- Used for prototyping

- Suitable for different types of gears

- Preparing casting molds

Up Milling vs. Climb Milling: Historical Background

In the late 1890s, conventional milling was the most popular method. However, during World War II, due to the increasing demand for high precision, climb milling began to enter the field. Today, climb milling is more common than conventional milling.

Advantages of Climb Milling

This section contains the applications of climb milling:

Better Surface Finish

Advanced tools and CNC machine tools provide better surface finish than steel and aluminum.

Extended Tool Life and Reduced Wear

Due to the lower surface roughness, friction is reduced, thereby reducing wear and increasing material life.

Lower Cutting Force and Heat Generation

Since climb milling is only used for softer materials such as aluminum and low-carbon steel, the required cutting force is lower, and the heat generated is also lower.

Simplified Workpiece Clamping

Because the cutting tool path runs in the direction of the workpiece, complex workpiece clamping is not required.

Climb Milling vs. Up Milling: Efficiency Advantages

Climb milling is effective for softer materials, and the conventional method is used for harder materials. Due to the automatic processing of CNC machine tools, climb milling can produce more efficient products.

Advantages of Conventional Milling

Let’s take a look at some advantages of conventional milling:

Stability and Control

Because the cutting tool runs in the opposite direction of the workpiece, it provides greater stability and control, thereby reducing vibration. Zero backlash allows better control of the tool due to low cutting force.

Ideal for Finishing and Small Cuts

To obtain the desired surface roughness, we often use the last round to remove unnecessary materials, which is called finishing. Conventional milling is considered a better choice for finishing and smaller cuts.

Zero Clearance for More Precise Cutting

In the case of conventional milling, it is relatively easy to achieve zero clearance and precise cutting. Zero clearance means there is no unnecessary gap on the workpiece after the milling operation. This allows other machines to move accurately and repeatedly without any unexpected movement.

When to Choose Up Milling for Specific Materials

Each milling method is applicable to different materials, that is, the milling method is limited by the material. The machining accuracy should be considered when choosing the cutting method.

- For softer materials, choose climb milling

- For harder materials, choose conventional milling

Disadvantages of Climb Milling

Each technology has its advantages and disadvantages; just as the advantages have been discussed above, the following are the disadvantages of this technology.

Possible Rebound and Stability Issues

The force of the tool pulls the workpiece and the workbench into the tool, resulting in unnecessary movement and positioning errors.

Not Suitable for Harder Materials

Harder materials such as high-carbon steel are difficult to process due to their greater brittleness. Therefore, using this technology will endanger the integrity of the material.

Risk of Tool Deflection and Inaccuracy in High-Speed Operations

You will find that the processing speed of CNC machine tools is very fast. Fast processing will make you face challenges such as tool deflection and dimensional inaccuracy. If your sample has defects (such as undercuts on the surface), such challenges will occur more frequently.

Climb Milling Direction and Its Challenges

These are some significant challenges in the climb milling process.

- Tool deflection

- Workpiece positioning error

- Backlash

- Harder materials

Disadvantages of Conventional Milling

Now, it’s time for you to be familiar with the disadvantages of conventional milling.

Surface Finish Issues in Conventional Milling

Due to the use of manual tools and the possibility of human error, products face some challenges, among which surface finish is the main one. It is difficult to obtain a smoother surface finish.

Higher Heat Generation and Its Impact on Tool Life

It causes high friction, which generates high heat, so the tool life is shortened because the cutting tool operates in the opposite direction to the workpiece rotation.

Increased Cutting Force and Its Impact on Stability

For example, when you climb a mountain, you have to exert more force, and the same is true for conventional milling technology. You need to apply greater cutting force to remove materials, which will affect stability.

Differences Between Climb Milling and Up Milling

Let’s understand some general differences between climb milling and up milling:

Climb Milling vs. Up Milling: Cutting Direction and Tool Movement

Climb Milling: As we have seen in the previous introduction part, the cutting path of climb milling is the same as the direction of the workpiece movement.

The tool moves clockwise.

Conventional Milling: The tool moves counterclockwise.

The direction of the cutting path is opposite to the direction of the workpiece movement.

Surface Finish Comparison: Climb Milling vs. Up Milling

Climb Milling: Compared with conventional milling technology, due to the automated operation and no manual participation in processing high surface finish.

Climb Milling vs. Up Milling: Which Method is Best for Different Materials?

This section will tell us which milling technology is best for different materials.

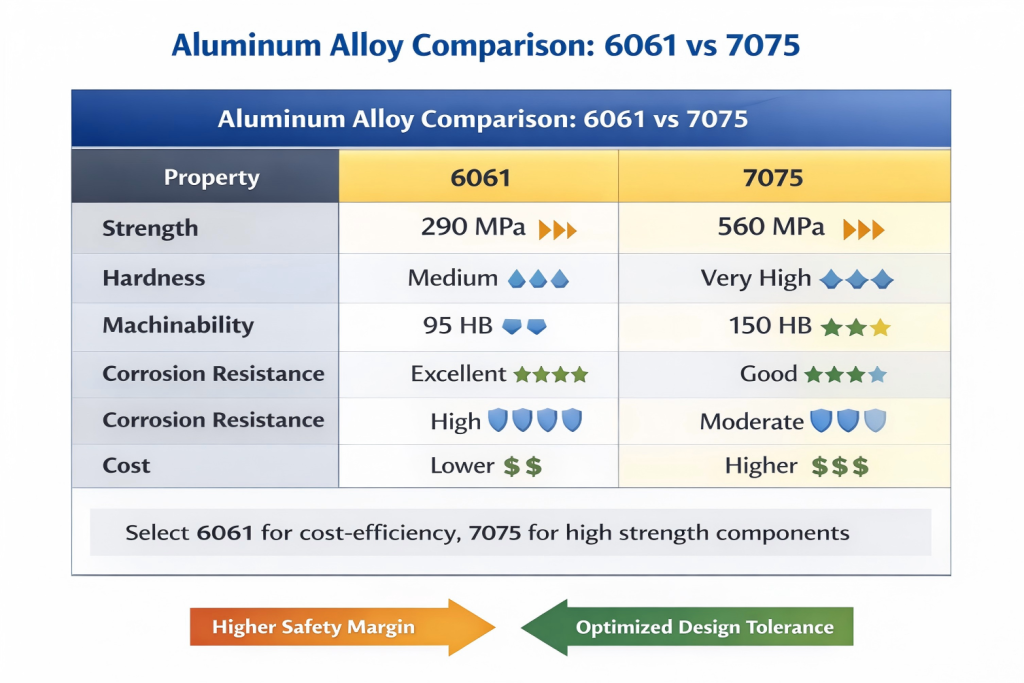

Climb Milling vs. Conventional Milling for Aluminum Alloys

Aluminum is a relatively soft material, and processing must adopt climb milling.

Climb Milling vs. Up Milling for Plastics

For softer materials such as plastics, climb milling is the most suitable technology because of its cutting tools.

Choosing Between Climb Milling and Up Milling: When to Use

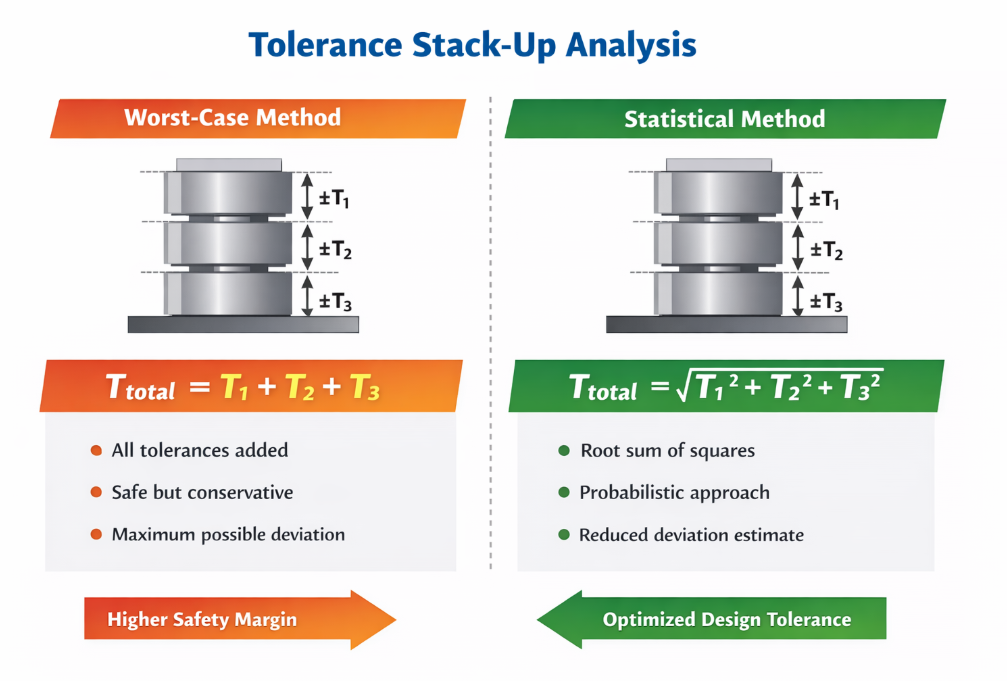

Climb Milling: Suitable for softer materials and tight tolerances

Conventional Milling: Suitable for harder materials

Choosing Climb Milling for Heavy Cutting and Soft Materials Processing

Because the tools installed in the machine can easily exert greater force ~1000N, that’s why it’s best to choose climb milling for heavier cutting and soft materials.

When to Use Conventional Milling for Finishing and Precision Machining

Conventional Milling => More suitable for thinner and finer cuts

Due to good control of tool force, it can produce smooth surfaces and higher precision

Factors to Consider: Part Geometry, Material Type, and Cutting Speed

Before choosing a milling method, these factors mentioned in the title should be considered. Proper consideration will help save money and time. If the material is hard and you choose climb milling, it will cause tool breakage, etc.

Understanding Milling Terms: Up Milling vs. Down Milling

You will understand how up milling and down milling are related to conventional milling and climb milling. Up milling and down milling are other names for such cutting methods used in the industry.

What is Up Milling? How is It Related to Up Milling?

Climb milling is like climbing a mountain, where force is applied in the opposite direction to the workpiece movement, which is why it is related to up milling.

What is Down Milling? How is It Related to Climb Milling?

The cutting tool moves downward. In climb milling, the cutting path is the same as the movement of the workpiece, so it is called down milling.

Climb Milling vs. Up Milling: Impact on Chip Thickness and Cutting Force

Climb Milling

First, the chip thickness increases first, then gradually decreases until the end. As a result

- Reduced cutting force

- Reduced tool wear

Conventional Milling

The chip thickness decreases first and then increases, resulting in:

- Higher cutting force

- More severe tool wear

Climb Milling vs. Up Milling in CNC Machines: Differences and Applications

Up Milling

- Cutting tool direction: opposite to the direction of workpiece movement

- Applications are in

- Rough machining

- Processing harder materials

Climb Milling

- Cutting tool direction: same as the direction of workpiece movement

- Applications are:

- Machining accuracy

- Finishing operations

- Processing softer materials

Practical Tips for Climb Milling and Up Milling

People should follow the following tips to avoid any problems:

How to Minimize Backlash in Climb Milling

The following tips will help you minimize backlash in climb milling.

- Use spring systems and double nuts as anti-backlash devices.

- The machine should be well maintained

- Preload the table

Adjusting Milling Parameters for Optimal Results

To obtain the best results or machining accuracy, carefully set the following parameters:

- Cutting speed

- Feed rate

- Depth of cut

Tool Selection and Its Impact on Milling Strategies

Choosing the right tool is very important for milling operations. It can save time, reduce material waste, and ensure the integrity of the tool. For example, the tool geometry should match the workpiece geometry.

Efficient Use of CNC Machines for Climb and Up Milling

If you meet the following conditions, CNC machine tools will produce parts with small tolerances and high precision:

- Carefully program the tool path

- Optimize tool changes and settings

- Use gap compensation

Climb Milling vs. Up Milling: Which is Best for Your Project?

If my project contains softer materials like aluminum, you should choose the climb milling process, and vice versa.

Start Your Next CNC Milling Part Project with Debaolong Seiko

Debaolong Seiko is a Chinese company equipped with the best CNC machines. We provide you with the processing of complex parts with high precision and small dimensional tolerances. Because the machines are very advanced, we can carry out mass production in a shorter time. Therefore, we deliver processed parts at a reasonable cost in the shortest possible time