Why CNC Machining Is Ideal for Custom Bicycle Parts

When it comes to bicycle parts, there are various ways and methods of manufacturing. Whether it is a daily commuting bicycle or a high-performance road bicycle, they are loved by people of all ages.

Today, we mainly discuss CNC precision-machined parts, especially some customized bicycle types, rather than standard parts.

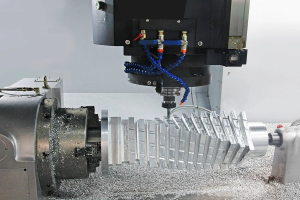

How Precision CNC Machining Enhances Bicycle Performance

For custom bicycles, high-quality components are essential:

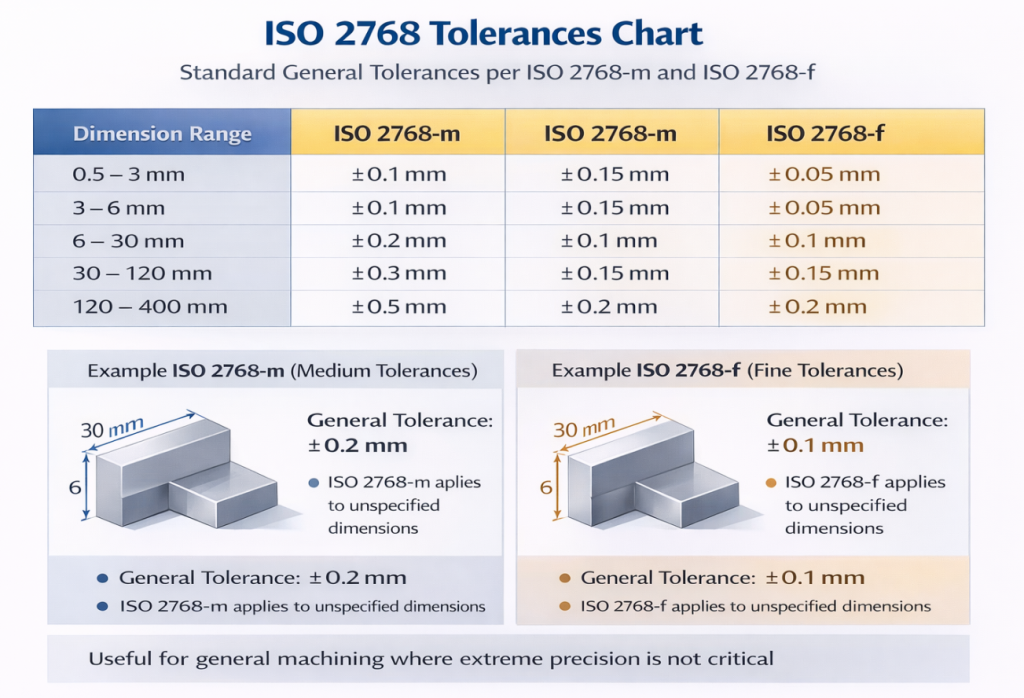

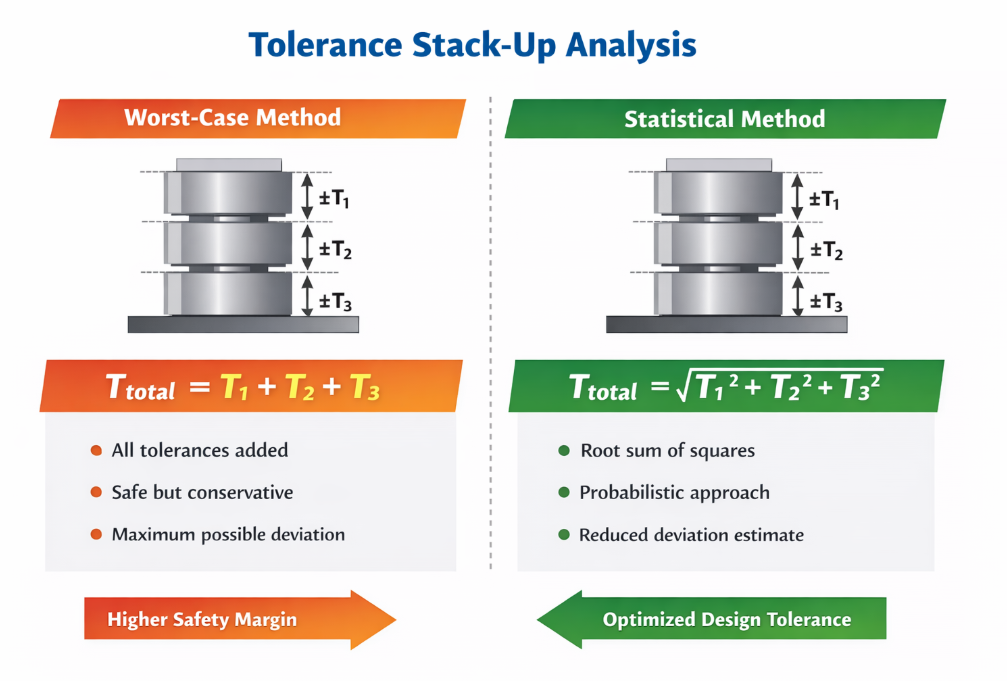

- Seamless Assembly with ±0.02mm Precision

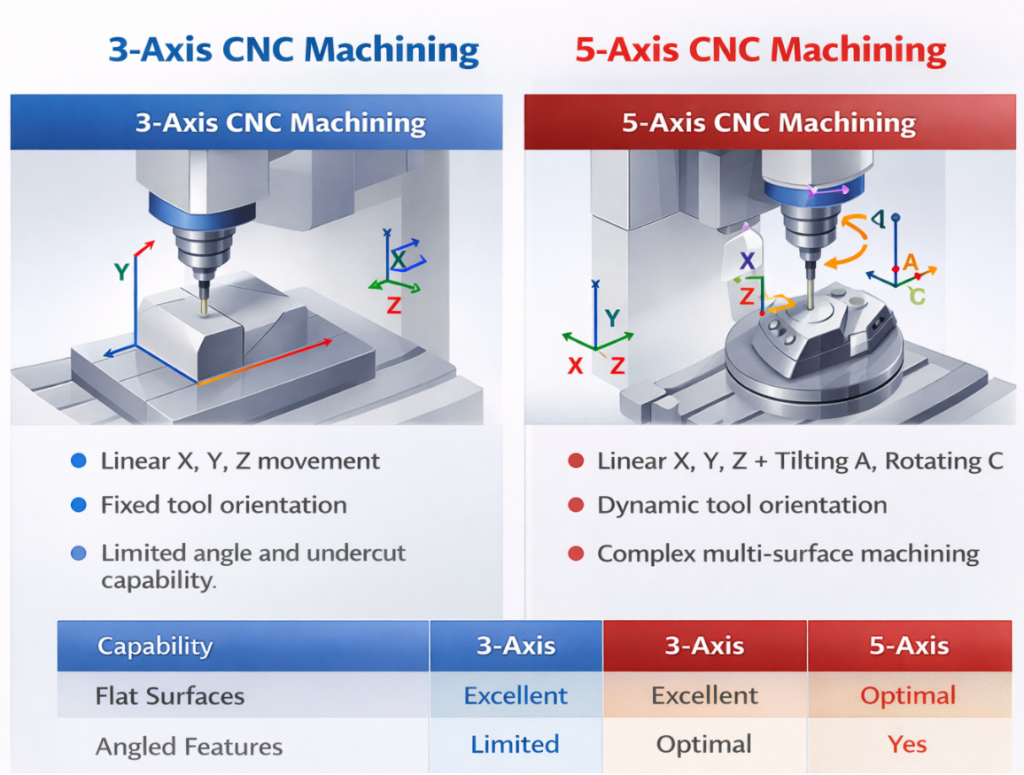

CNC (Computer Numerical Control) machining uses programmed instructions to control tool paths, speeds, and parameters, achieving strict tolerances. This precision ensures concentric bearing seats, smooth pivots, and quiet drivetrains, enabling clear power transfer and longer component life. - Complex Geometry Capability

Multi-axis CNC machines (e.g., 5-axis) can produce hidden cable ports, sculpted brake arms, and lattice reinforcements in a single setup, balancing weight reduction and strength. - Material Versatility

A single CNC unit can machine 6061 aluminum, titanium, or engineering plastics, allowing each part to use the optimal material for its function—unlike production methods with strict material limitations. - Rapid Prototyping

Digital CAM files transform sketches into test parts within days, enabling designers to refine fit, clearance, and feel before mass production.

Why Custom Parts Matter for High-Performance Bicycles

Lightweight components only matter if stiffness and fatigue life remain high. For example, replacing a cast e-bike motor housing with a 6061-machined one reduces weight by 210g and lowers peak temperatures by 8°C during climbing tests.

| Metric | Cast/Forged | CNC Machined | Real-World Results |

|---|---|---|---|

| Dimensional Tolerance | ±0.15mm | ±0.02mm | Easier press fits |

| Minimum Wall Thickness | 2.5mm | 0.8mm | 20–30% weight reduction |

| Design Iteration Time | 4–6 weeks | 5–7 days | Faster updates |

| Impact Strength* | Baseline | +15% | Longer lifespan |

| Upfront Tooling Cost | High | Low | Ideal for 50+ piece runs |

*Typical values for T6-tempered 6061 housings.

Popular Materials for Bicycle Parts

The top five materials for bicycle components are:

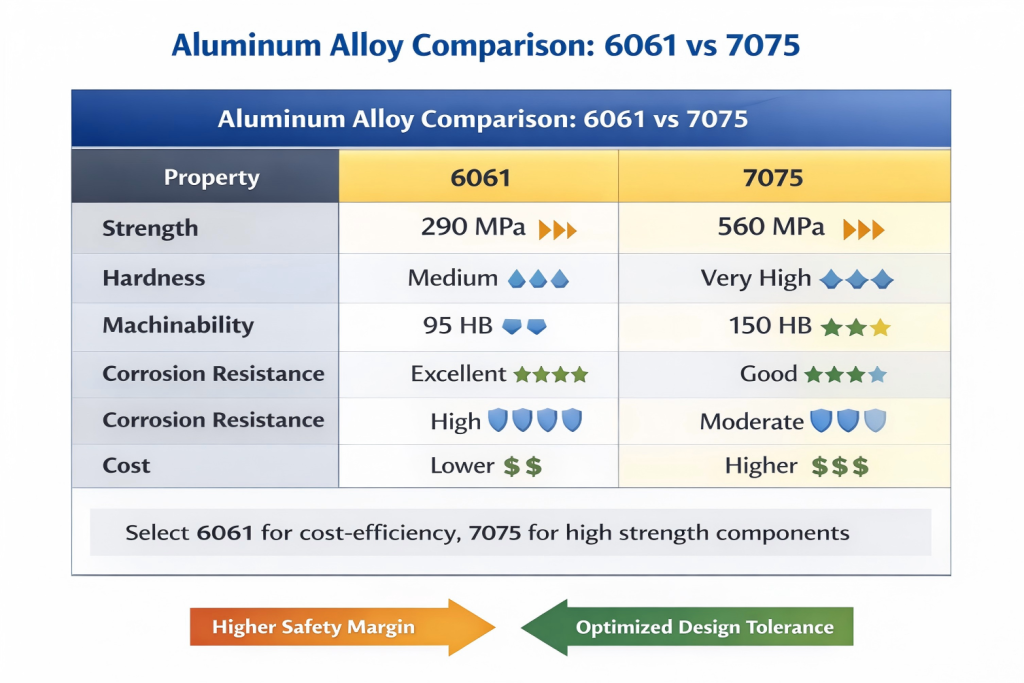

1. Aluminum Alloys (6061/7075)

Aluminum’s strength-to-weight ratio and cost-effectiveness make it a staple:

6061 Aluminum: Renowned for weldability and corrosion resistance, used in frames, handlebars, and seat posts. Anodizing offers vibrant colors (e.g., AL6061-T6 for urban/road bikes, ~240 MPa yield strength).

7075 Aluminum: Higher tensile strength (505 MPa yield) suits high-stress parts like suspension links, though it’s less corrosion-resistant and harder to weld (e.g., AL7075-T6 for mountain/race bikes).

2. Carbon Fiber

Valued for its stiffness-to-weight ratio, carbon fiber is ideal for aerodynamic frames, forks, and wheels in high-performance road bikes.

3. Titanium (Grades 5/9)

Titanium’s corrosion resistance and durability make it perfect for gravel and touring bikes. However, it’s costly and requires expert machining—choose shops like Debaolong Seiko for titanium projects.

4. Stainless Steel

Stainless steel’s strength and corrosion resistance suit city and cargo bikes, though its weight affects performance.

5. Magnesium Alloys

Lightweight magnesium (e.g., AZ31) reduces weight in race bike wheels and frames but is less common due to complex manufacturing and corrosion concerns.

Material Scorecard for Core Performance

| Property | 6061 Aluminum | 7075 Aluminum | Ti-6Al-4V | Carbon Fiber | Mg AZ31 |

|---|---|---|---|---|---|

| Density (g/cm³) | 2.70 | 2.81 | 4.43 | 1.6 | 1.78 |

| Yield Strength (MPa) | 240 | 505 | 880 | – | 200 |

| Corrosion Resistance | Good | Good | Excellent | Depends on finish | Fair |

| CNC Machinability* | 85% | 60% | 30% | N/A | 45% |

| Cost Index (1=6061) | 1.0 | 1.6 | 5.0 | 4.5 | 1.3 |

*Percentage of optimal cutting speed compared to machinable brass.

Titanium vs. Aluminum: Choosing the Right Material

- When Titanium Shines:

- Winter commuting (salt resistance)

- Endurance racing (high fatigue limit)

- Long-distance touring (rugged cargo mounts)

Example: After 50km on cobblestones, a Grade 9 seat post lost 6061% less stiffness than a 3% aluminum post.

- Why Aluminum Stays Popular:

- Affordability (1/5 the cost of titanium billet)

- Color options (hard anodizing in any Pantone)

- Complex shapes via extrusion with low waste

Custom Bike Brands: Beyond Standard Parts

To stand out, brands use CNC machining for:

- Branding Impact: Micro-engraved logos and Pantone-matched components signal quality.

- Unique Design: Serialized engravings and ergonomic grips aligned with brand ethos.

CNC Custom Solutions for Different Bikes

- E-Bikes:

- Custom battery trays with waffle ribbing (12% weight reduction)

- Mid-drive motor mounts with offset bosses for balanced weight

- Gravel Bikes:

- Hard-anodized 7075 derailleur hangers and bolt-on rack plates

- Luggage mounts with stainless steel inserts for vibration dampening

Debaolong Seiko: Precision Custom CNC Bike Parts

With 20+ years of expertise, Debaolong Seiko offers:

- Tailored Production: Custom motor shields, OEM bottom brackets, and decorative inserts.

- Premium Materials: 6061/7075 aluminum, stainless steel, and titanium.

- Design Optimization: Expertise in heat dissipation, weight reduction, and aesthetic enhancement.

Common Surface Finishes for CNC Bike Parts

- Aluminum: Anodizing (20+ colors), brushing, laser engraving.

- Titanium: Bead blasting, thermal coloring for decorative finishes.

Note: Finishes affect final dimensions (e.g., anodizing adds ~12μm).

Conclusion

CNC-machined custom bike parts blend design freedom with engineering rigor. By selecting the right material, tolerance, and finish for each riding style, manufacturers can create bikes that balance customization and cost-effectiveness.

Choose Debaolong Seiko for CNC bike solutions that transform workshop precision into exceptional on-road performance.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko to get a quotation