Anodized Aluminum vs. Anodized Steel: A Comprehensive Cost ComparisonWhen comparing the costs of anodized aluminum and anodized steel, it’s essential to understand their unique properties, applications, and production methods. Below, we detail the differences between anodized aluminum, stainless steel, and galvanized steel, focusing on material composition, advantages, and disadvantages. Which is cheaper: anodized aluminum or anodized steel?

1. Material Composition: Anodized Aluminum vs. Stainless Steel

Anodized Aluminum

This material originates from aluminum, processed via an electrolytic process to form a protective oxide layer on its surface. Its primary component is aluminum, enhanced by anodizing to improve durability and corrosion resistance.

Stainless Steel

Stainless steel is an alloy primarily composed of iron, chromium, nickel, and other elements, renowned for its exceptional corrosion resistance and strength. Unlike aluminum, it doesn’t require an anodized layer to achieve these properties.

2. Key Characteristics: Strength, Corrosion Resistance, and Appearance

Corrosion Resistance

- Anodized Aluminum: The oxide layer enhances corrosion and wear resistance, though its performance generally lags behind stainless steel in extreme environments.

- Stainless Steel: Naturally resistant to most corrosive agents due to its chromium and nickel content.

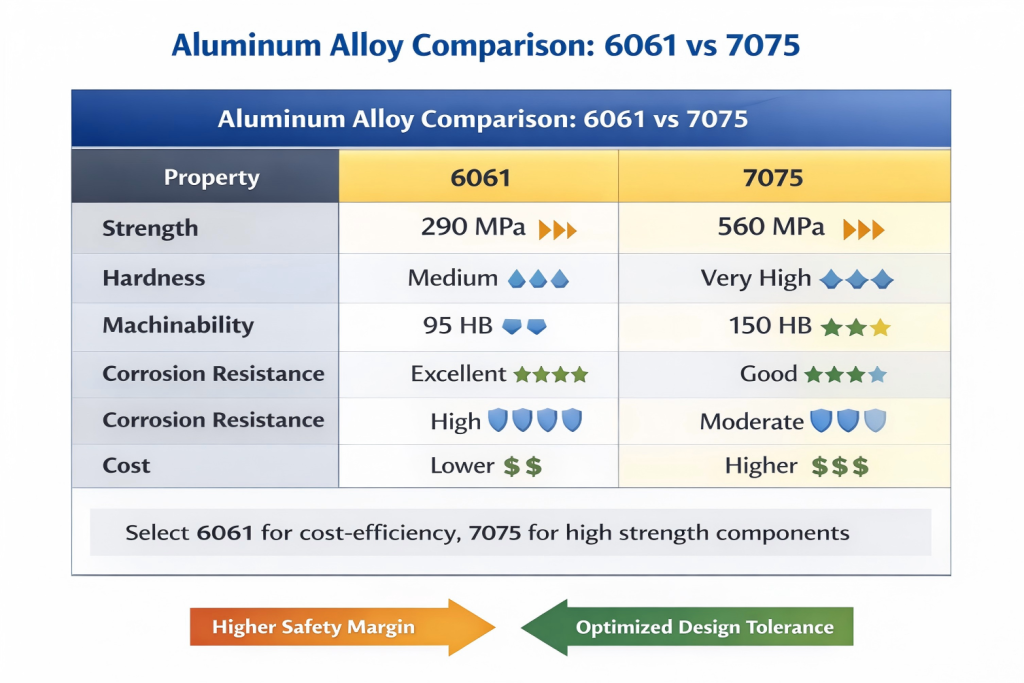

Strength and Hardness

- Anodized Aluminum: Lighter and less rigid than stainless steel. While the anodized layer adds hardness, it can’t match steel’s structural integrity.

- Stainless Steel: Offers superior strength, withstanding high physical stress and wear.

Appearance and Customization

- Anodized Aluminum: Known for its versatile aesthetics. The anodized layer can be dyed in various colors, making it suitable for decorative applications.

- Stainless Steel: Maintains a uniform polished silver appearance, fitting for industrial and modern designs.

3. Cost Comparison

Anodized Aluminum

- Production Cost: Manufacturing anodized aluminum involves a complex anodizing process requiring energy and chemical inputs, increasing total costs.

- Market Applications: Used in electronics, home decor, and premium automotive parts, valued for its light weight and customizable appearance.

Stainless Steel (Analogous to Anodized Steel)

- Production Cost: Stainless steel is costlier than ordinary steel due to chromium and nickel content. Anodized stainless steel is less common, primarily used for aesthetic purposes, making its cost comparable to or slightly higher than anodized aluminum in specialized applications.

- Market Applications: Favored in chemical, medical, and construction industries for its durability.

Conclusion: Generally, anodized aluminum is costlier than ordinary stainless steel but comparable in cost to specialized anodized steel.

4. Applications and Cost-Effectiveness

Anodized Aluminum

- Advantages: Lightweight, corrosion-resistant, and aesthetically versatile.

- Disadvantages: Lower strength and higher cost compared to non-anodized aluminum or galvanized steel.

- Best Suited For: Electronics, furniture, decorative panels, and applications where lightweight design matters.

Stainless Steel

- Advantages: Exceptional strength and corrosion resistance.

- Disadvantages: Heavier and less flexible in design compared to aluminum.

- Best Suited For: High-pressure environments, food processing equipment, medical tools, and structural applications.

5. Cost Comparison: Anodized Aluminum vs. Galvanized Steel

Anodized Aluminum

- More energy-intensive production and higher costs, used for high-end applications.

Galvanized Steel

- Affordable due to its protective zinc coating, widely used in construction and basic consumer goods.

Verdict: Galvanized steel is significantly cheaper than anodized aluminum, making it a more cost-effective choice for large-scale or non-decorative uses.

FAQs

- What are the main cost differences between anodized aluminum and anodized steel?

Anodized aluminum typically has higher production costs due to its complex manufacturing process, while anodized steel (e.g., stainless steel) is more durable, with broader industrial applications that often balance cost with functionality. - Which is lighter: anodized aluminum or stainless steel?

Anodized aluminum is lighter, ideal for weight-sensitive applications like aerospace and electronics. - Why is anodized aluminum more expensive than galvanized steel?

The anodizing process involves extra steps requiring more resources and energy, whereas galvanized steel production is simpler and more cost-effective. - Can anodized aluminum replace stainless steel in industrial applications?

It depends on the application. Anodized aluminum suits lightweight, non-structural parts, while stainless steel is better for high-strength, high-pressure environments. - How does the durability of anodized aluminum compare to anodized steel?

Anodized steel, especially stainless steel, is more durable due to its inherent material properties and higher wear resistance. - Which industries commonly use anodized aluminum?

Electronics, automotive, and home decor industries often use anodized aluminum for its aesthetic versatility and lightweight nature.

Conclusion

When evaluating costs between anodized aluminum and anodized steel, the specific requirements of your project—such as weight, strength, durability, and aesthetics—will play a pivotal role. While anodized aluminum is typically costlier and suited for decorative or lightweight applications, anodized steel offers unmatched durability for industrial use.

For more information, please contact Debaolong Seiko.