Today, industries like metalworking, engraving, and woodworking heavily rely on CNC (Computer Numerical Control) equipment. Their accuracy, productivity, and ability to handle complex tasks are well-known attributes. For years, Chinese-manufactured CNC machines have drawn attention, primarily due to their affordability. However, many potential buyers still ask: Are Chinese CNC machines good?

This article examines the functionality, reliability, performance, and quality of Chinese-made CNC machines to answer this question. We’ll also discuss their lifespan, suitability for small businesses, and provide tips for selecting high-quality machines.

The Quality of Chinese CNC Machines

Price is often the first factor that comes to mind when thinking about Chinese products. Questions about quality arise because Chinese CNC machines are significantly cheaper than their European or American counterparts. Chinese manufacturers were once known for cutting corners, but in recent years, many have raised production standards—especially in fields like CNC technology.

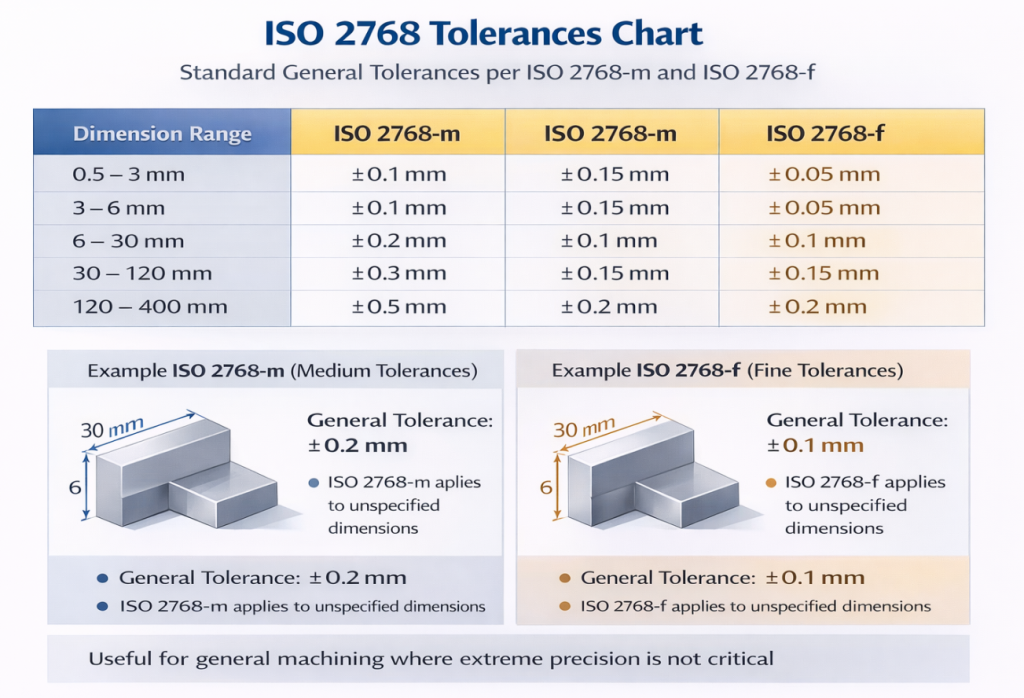

- Advanced Technology: Many Chinese manufacturers now use cutting-edge technology to produce CNC machines that meet international quality standards, making them more precise, durable, and reliable.

- Improved Quality Control: Factories have adopted stricter quality control processes to ensure their machines can compete globally. Today, many Chinese CNC machines carry certifications like ISO9001, guaranteeing specific quality and performance levels.

- Global Collaboration: Some Chinese manufacturers partner with international companies to produce high-quality machines, allowing them to adopt better designs and use higher-grade materials.

Overall, the quality of Chinese CNC machines has significantly improved. They are used in industries like metalworking, woodworking, and automotive because they deliver high-quality results at affordable prices.

Are Chinese CNC Machines Good?

Now, let’s address the main question: Are Chinese CNC machines good? The answer isn’t a simple “yes” or “no,” as it depends on factors like the specific machine, manufacturer, and intended use. Investing in a Chinese CNC machine can be a smart choice, especially if you seek cost-effective options. To ensure you get a machine that meets your needs, choosing a reliable manufacturer is crucial. Here are key points to remember:

- Affordability: Chinese-made CNC machines are far cheaper than European or American models, making them ideal for small and medium-sized companies that can’t afford luxury brands. Cheaper doesn’t necessarily mean lower quality—many Chinese CNC machines offer excellent value for money.

- Varied Quality: The quality of Chinese CNC machines varies by manufacturer. While some may offer cheaper, less durable equipment, others produce high-quality machines that perform well and last long. Researching brands before purchasing is essential.

- Customer Satisfaction: Many users report positive experiences with Chinese CNC machines, particularly in industries like woodworking and metalworking. They find the machines efficiently meet their production needs.

- Customization Options: Many Chinese CNC manufacturers offer customizable features, allowing customers to choose specific parts, applications, or functions based on their needs. This flexibility adds significant value by letting you tailor the machine to your requirements without overpaying for unnecessary features.

- Spare Parts Availability: A key advantage of buying Chinese CNC machines is the ready availability of spare parts. Many Chinese manufacturers provide accessible replacement parts that ship quickly and cost less than those for Western machines, reducing downtime and ensuring smooth production.

Performance and Reliability of Chinese CNC Machines

Performance and reliability are critical for any business, as they directly impact productivity. How do Chinese CNC machines fare in these aspects?

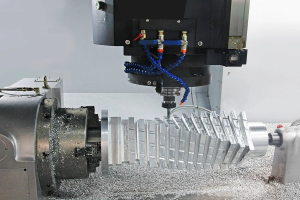

Performance

Chinese CNC machines are known for their high performance in general tasks like cutting, milling, and engraving. They can handle various materials, including wood, plastic, and metal. Many can operate at high speeds, enabling businesses to produce more in less time.

Advanced models suit businesses needing fine details—such as jewelry production or signage engraving— as they handle complex designs and high-precision tasks. In performance, many Chinese CNC machines rival those made in Europe and the U.S., especially for non-industrial use.

Reliability

Reliability is a key component of any CNC machine. With proper maintenance, Chinese CNC machines can be highly reliable. Regular upkeep—such as lubrication, cleaning, and component checks—helps extend their lifespan. However, when buying from lesser-known manufacturers, some customers occasionally report issues with warranty claims or customer support.

Chinese CNC machines are reliable with regular maintenance and suitable for various applications. Choosing a model that matches your manufacturing requirements is essential.

Common Features of Chinese CNC Machines

Chinese CNC machines typically offer a range of features that make them versatile and user-friendly. Here are some common features:

- Affordability: The biggest selling point of Chinese-made CNC machines is their affordability. They cost significantly less than models from other countries, making them accessible to businesses of all sizes.

- Diverse Models: Chinese CNC machines come in a wide range, from entry-level desktop models for beginners to industrial-grade machines for high-volume production. This variety lets you choose a machine that meets your unique needs.

- User-Friendly Interfaces: Many Chinese CNC machines come with easy-to-use control panels and intuitive software, making them accessible even to newcomers with limited CNC knowledge.

- Versatility: Most Chinese CNC machines can handle multiple tasks, such as engraving, cutting, milling, and drilling. This versatility makes them suitable for industries like woodworking, metalworking, and plastic manufacturing.

- Customization Options: With customization features offered by some Chinese manufacturers, you can adjust the machine to meet your production needs—whether by upgrading the spindle or adding functions, customization enhances the machine’s utility.

How to Choose a High-Quality Chinese CNC Machine

Choosing the best CNC machine can be challenging, especially with so many options. Here’s a guide to help you select a high-quality Chinese CNC machine, enabling you to make an informed decision that aligns with your company’s needs:

- Research Manufacturers: Not all Chinese companies produce machines of the same quality. Look for manufacturers with a good track record, positive reviews, and reliable customer service. Seeking international certifications like ISO9001 also helps.

- Understand Your Needs: Define your machine requirements before purchasing. Will you process wood, metal, or plastic? Do you need extremely high precision? Understanding your needs makes it easier to choose the ideal machine for your business.

- Check Warranty and Support: A good warranty provides peace of mind in case of issues. Ensure the manufacturer or supplier offers customer support so you can get help when needed.

- Read Reviews: User reviews offer valuable insights into a machine’s performance and reliability. Look for reviews from businesses similar to yours to better understand how the machine will perform in your environment.

- Evaluate Technical Specifications: Pay close attention to the CNC machine’s technical specifications, including speed, cutting precision, and material range. Ensure the specs match your production needs.

Are Chinese CNC Machines Suitable for Small Businesses?

Cost is often a primary consideration for small businesses when purchasing equipment. Chinese CNC machines are popular among SMEs (small and medium-sized enterprises) because they’re typically cheaper than Western counterparts. Are they suitable for such companies?

Chinese CNC machines are an excellent solution for small companies for several reasons. First, they’re affordable, making them accessible to businesses on tight budgets. Local enterprises can compete in the market by making cost-effective investments in CNC technology.

Chinese CNC machines often offer scalability, meaning companies can start with a simple model and upgrade as they grow. This flexibility is ideal for small businesses that plan to expand and need equipment that adapts to increasing production demands.

Ease of use is another benefit. Chinese CNC machines typically feature user-friendly interfaces, making them easy to operate. Small companies benefit from this, as it saves time and reduces the need for extensive training. Overall, Chinese CNC machines balance affordability and functionality, making them a great choice for small businesses looking to streamline operations.

Advantages and Disadvantages of Buying Chinese CNC Machines

Like any product, Chinese CNC machines have their own advantages and disadvantages. In-depth research and consideration of your specific needs will help you make a better decision. Let’s examine the pros and cons:

Advantages of Chinese CNC Machines

- Affordability: Chinese CNC machines are significantly cheaper than those produced in Western countries, making them ideal for small businesses and hobbyists with limited budgets.

- Versatility: Many Chinese-made CNC machines can perform a wide range of tasks, including milling, engraving, and cutting various materials like plastic, metal, and wood. This adaptability suits multiple applications.

- Customizability: Some manufacturers allow customization of their CNC machines, meaning you can modify features or add components based on your specific needs. Customization helps you get a machine tailored to your business requirements.

- Diverse Models: China offers a wide range of CNC machines for sale, from small desktop models for hobbyists to large industrial machines for heavy manufacturing—catering to various needs.

- Rapid Production: Chinese manufacturers often have faster production times, meaning you can get your machine quicker than from other countries, allowing you to start projects faster.

- Abundant Spare Parts: Many Chinese manufacturers provide spare parts, ensuring you can replace components quickly when needed, reducing downtime and maintaining operational efficiency.

Disadvantages of Chinese CNC Machines

- Inconsistent Quality: The quality of Chinese CNC machines varies by manufacturer. While some are high-quality, others may not meet your expectations. Researching and choosing a reputable brand is crucial.

- Limited Customer Support: Some Chinese manufacturers may offer limited customer support, especially for international buyers, making it difficult to get help when issues arise and causing production delays.

- Warranty Challenges: Warranty claims can sometimes be difficult to process. Depending on the manufacturer, you may face challenges when trying to claim warranty services, leading to frustration if problems occur.

How Long Do Chinese CNC Machines Last?

The lifespan of a CNC machine depends on factors like quality, usage patterns, and maintenance. How long do Chinese CNC machines typically last?

High-quality Chinese CNC machines from reputable manufacturers have a long lifespan. Some users report their machines lasting over a decade with proper maintenance. Regular maintenance—including cleaning, lubrication, and replacing worn parts—can extend any CNC machine’s lifespan. Most Chinese CNC machines come with maintenance guides, and following them can significantly prolong the machine’s life.

The more frequently a machine is used, the faster it may wear out. However, a well-built Chinese CNC machine can last for years even with heavy use. With regular maintenance, high-quality Chinese CNC machines offer excellent cost-effectiveness and a long service life.

Conclusion

Many companies can benefit from using Chinese CNC equipment. They come in various models, are affordable, and are functional. Many also offer customization to meet specific requirements. Choosing a reliable manufacturer is crucial because quality can vary.

Investigate your options, as customer service and warranty issues may arise. In summary, Chinese CNC machines can help improve efficiency and expand your company with the right strategy. By evaluating the advantages and disadvantages, you can choose the machine that best fits your needs.

For more information, please contact Debaolong Seiko.